Choosing the best PPR welding machine can be a daunting task. With so many options available, it’s easy to feel overwhelmed.

PPR welding machines are essential tools for plumbers and construction professionals. They ensure strong, reliable joints in plumbing and heating systems.

The right machine can make a significant difference in your project’s success. It should offer consistent heat distribution and be easy to use.

Portability and durability are also crucial factors to consider. A machine that is easy to transport and built to last will serve you well.

In this guide, we’ll explore the top features and models to help you make an informed decision.

Understanding PPR Welding Machines: Basics and Applications

PPR welding machines are specialized tools for joining polypropylene random (PPR) pipes. These pipes are widely used in plumbing and heating systems due to their durability and resistance to corrosion.

The welding process involves heating the pipe ends until they melt and then fusing them together. This results in strong and leak-proof joints essential for long-lasting plumbing installations.

These machines have various applications, including:

- Residential and commercial plumbing

- Heating systems

- Industrial pipe installations

Understanding the basics of PPR welding machines and their applications will guide you in choosing the right equipment for your projects.

Key Features to Look for in the Best PPR Welding Machine

When selecting a PPR welding machine, several key features distinguish the best from the rest. These features ensure efficient and effective operation.

First, consider machines with adjustable temperature settings. This flexibility allows for welding different sizes and materials of PPR pipes, enhancing versatility.

Portability is crucial, especially for on-site work. Opt for lightweight machines that are easy to transport and handle.

Additional important features to consider include:

- Quick heating time for increased efficiency

- Durable construction for long-term use

- Safety features like thermal protection

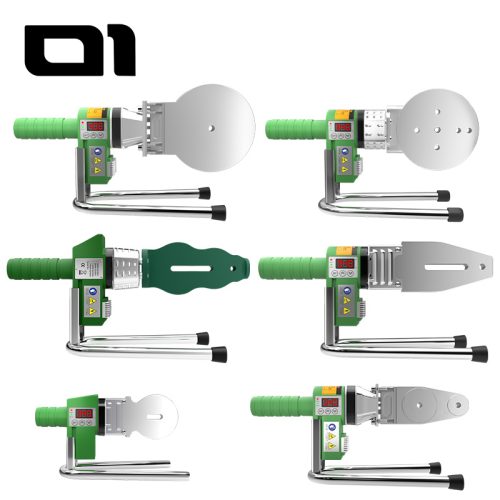

Also, look for machines with interchangeable welding heads. These provide the flexibility to work with various pipe diameters, which is often necessary in diverse applications.

Lastly, a machine that includes a comprehensive set of accessories, such as a carrying case and a pipe cutter, adds significant value. Such features optimize convenience and boost productivity in your welding projects.

Types of PPR Welding Machines: Which One Suits Your Needs?

PPR welding machines come in different types, each offering unique advantages. Choosing the right type depends on your specific project requirements and application needs.

Manual welding machines are simple and cost-effective. They’re ideal for smaller projects or for DIY enthusiasts who value control. However, they may require more skill and time.

On the other hand, automatic welding machines offer quick and consistent results. They are suitable for larger or commercial projects where efficiency is crucial. These types often feature advanced technology to streamline the welding process.

Consider these when selecting a machine:

- Manual welding machines: budget-friendly and adaptable

- Automatic welding machines: fast and consistent

- Choose based on project size and complexity

Selecting the right type will ensure that you achieve high-quality and reliable welds, enhancing the durability and efficiency of your plumbing systems.

features, ensuring you find the perfect match for your specific needs.

Comparing Performance: Temperature Control, Heating Time, and Safety

The performance of a PPR welding machine heavily depends on its temperature control features. Machines with digital displays provide precise temperature settings, crucial for consistent weld quality.

Heating time is another vital factor. Machines with quick heating times reduce waiting periods, boosting productivity. This feature is particularly beneficial in large projects with tight deadlines.

Safety should never be compromised. Quality machines are equipped with thermal protection and ergonomic designs, reducing the risk of accidents. Essential safety features include:

- Thermal protection: Prevents overheating

- Ergonomic design: Reduces user fatigue

- Stable stand: Offers machine stability

Considering these performance aspects ensures you select a machine that delivers reliable, safe, and efficient operation.

Portability, Durability, and Ease of Use

Portability is a key feature when choosing the best PPR welding machine. Lightweight models make on-site work simpler. A machine with a sturdy carrying case enhances transport convenience.

Durability is equally crucial. Machines crafted from robust materials withstand wear and tear, ensuring longevity. A well-built unit offers consistent performance across various projects.

Ease of use transforms the welding experience. User-friendly controls and clear instructions minimize setup difficulties. Important aspects include:

- Lightweight design: For easy transport

- Robust construction: Ensures long-term use

- Simple controls: Improve usability

These features collectively enhance the machine’s versatility and operational efficiency.

Maintenance Tips for Long-Lasting Performance

Proper maintenance extends the life of your PPR welding machine. Regular care ensures optimal performance and reduces downtime. Follow these simple tips to keep your equipment in top shape.

Key maintenance practices include:

- Clean regularly: Remove debris after each use.

- Inspect parts: Check for wear and tear.

- Store properly: Keep in a dry, safe place.

Consistent upkeep not only preserves functionality but also enhances safety and efficiency. Investing time in maintenance pays off in durability and reliability.

Frequently Asked Questions About PPR Welding Machines

Choosing a PPR welding machine involves many considerations. To help, we’ve addressed some common questions.

What should I consider before buying?

- Versatility: Can it handle various pipe sizes?

- Heating time: Is it fast and efficient?

- Safety: Are there adequate safety features?

Understanding these aspects can guide your purchase. Always weigh options based on specific project needs. With the right information, making an informed choice becomes easier.

Conclusion: Choosing the Best PPR Welding Machine for Your Projects

Selecting the best PPR welding machine hinges on understanding your specific needs and project requirements. Factors like temperature control, portability, and safety should rank high on your list.

Balancing cost with quality and features ensures a worthwhile investment. By considering reputable brands and reading reviews, you can gain insights into performance and reliability. With careful consideration, your chosen machine will deliver high-quality welds and enhance your project’s success.