Heating Phase

The PPR fusion welder heats its welding mold via built-in high-efficiency electric heating elements (e.g., ceramic heating tubes).

Mold temperature is the most critical parameter for welding quality, typically set between 200°C – 400°C. This must be strictly calibrated based on the PPR material grade, pipe dimensions, and environmental conditions.

Precision Temperature Control (Core Technology):

Modern high-performance PPR fusion welding machines universally adopt closed-loop temperature control systems, including:

- High-accuracy temperature sensors: Monitor real-time mold surface temperature.

- Intelligent control modules (e.g., PID algorithms): Compare sensor feedback with preset values to dynamically adjust heating power.

- Rapid-response actuators: Ensure immediate heat adjustment per control commands.

This system prevents material degradation (carbonization) from overheating or weak fusion (“cold welds”) from insufficient heat—foundational for high-quality PPR pipe joints. Temperature stability is typically maintained within ±2°C ~ ±5°C.

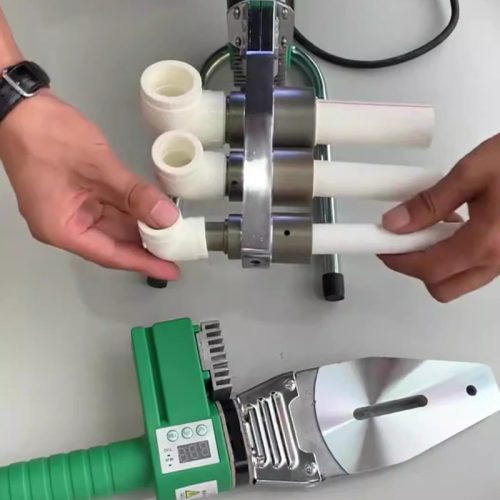

Melting Phase

Clean PPR pipe ends and fitting sockets are inserted vertically and without rotation into the heated mold (equipped with pipe-end and socket-end dies).

Through thermal conduction, the fusion surfaces reach a molten state within the preset time, forming a uniform melt layer of optimal thickness—the critical zone for joint formation.

Fusion & Connection Phase

Once heating completes and melt layers reach the optimal welding temperature (slightly above the material’s melting point), swiftly remove the pipe and fitting from the welding mold.

Immediately insert the pipe into the fitting socket straight and without rotation to the preset depth, applying constant pressure.

Pressure ensures:

- Tight contact between molten surfaces

- Molecular inter-diffusion

- Elimination of air bubbles

Resulting in a uniform, continuous fusion interface.

Cooling & Solidification Phase

After connection, the PPR fusion welder stops heating.

Maintain constant pressure while the joint cools naturally in ambient air.

Critical: Never move or stress the joint during the prescribed cooling time. Pressure maintenance prevents gaps or stress concentration from shrinkage, ultimately creating a high-strength molecular bond.

Automation & Smart Control (Advanced PPR Fusion Welder Features)

Advanced PPR pipe welding machines integrate Programmable Logic Controllers (PLC) and Touchscreen HMIs (Human-Machine Interfaces).

Users can intuitively set and store welding parameters on the HIM for different pipe diameters and materials, including:

- Temperature settings

- Heating time

- Changeover time (from heating end to connection start)

- Fusion pressure (or insertion depth)

- Cooling time

The system auto-executes programs, ensuring consistent, repeatable PPR pipe connections while significantly boosting welding efficiency and process reliability.