Essential Tools & Preparation

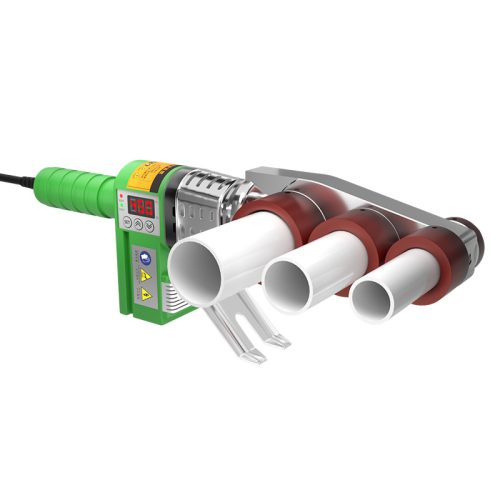

- Temperature-Controlled Welder

Use equipment maintaining 260°C±5°C – deviations cause weak joints or material degradation. - Precision Matched Dies

Select dies matching exact pipe diameter (DN20/DN25, etc.). Incorrect sizing creates uneven fusion. - Contamination-Free Cleaning

Wipe pipe ends and fittings with >99% isopropyl alcohol and lint-free cloths.

6-Step Fusion Protocol

- Square Cutting

Use PPR-specific cutters for burr-free, perpendicular ends – angled cuts cause leaks. - Depth Marking

Clearly mark insertion depth lines on pipes (never estimate visually). - Simultaneous Heating

Insert pipe and fitting straight onto heated dies. Adhere strictly to timing:- DN20: 5 seconds | DN25: 7 seconds (confirm with manufacturer data).

- Straight Assembly

Swiftly push pipe straight into fitting to the depth mark. Rotation is prohibited (fractures molecular bonds!). - Undisturbed Cooling

Immobilize joints for ≥2 minutes (longer for large diameters). Movement creates stress cracks. - Quality Verification

Inspect for uniform double bead formation – no cold joints or carbonization.

Critical Reinforcement (International Compliance)

- Material Consistency

Use same-brand, same-batch PPR pipes/fittings (ISO 15874/DIN 8077 compliant). Mixing brands causes joint failure. - Environmental Control

- Low temperature (<5°C): Increase heating time 50% + insulate joints

- High temperature (>40°C): Reduce heating time + avoid direct sunlight

- Dry, windless conditions only – no rainy/snowy operations

5 Critical Errors to Avoid

| Error | Consequence | Prevention |

|---|---|---|

| Rotating during fusion | Molecular bond failure | Strictly straight insertion |

| Temperature/time error | Cold joints or carbonization | Calibrate to 260°C±5°C |

| Incorrect depth | Leaks/flow obstruction | Depth marks + caliper check |

| Moving during cooling | Stress fractures | Secure supports + full cooling |

| Incomplete cleaning | Contaminated interface | Two-way alcohol wiping |

Core Principle: Achieve permanent, maintenance-free PPR systems by adhering to ISO fusion standards. Remember the 9-Character Rule: “No Rotation, Precise Temperature, Exact Depth” – the foundation of zero-leak engineering.