In the world of plumbing, having the right tools is crucial to getting the job done efficiently and effectively. With technology continuously evolving, plumbing tools have become more sophisticated, yet intuitive to use, allowing plumbers to deliver high-quality work with ease. Among these essential tools, the PPR welding machine stands out as a vital asset for any professional plumber. Whether you are dealing with installing new pipelines or repairing existing ones, understanding and using a PPR welding machine can significantly improve the quality and durability of your work.

For many plumbers, the investment in quality tools can make the difference between a successful job and a botched one. The PPR welding machine exemplifies this, offering precision and consistency that older, traditional methods lack. In a competitive industry where reputation is everything, mastering the use of such advanced tools is not just beneficial but necessary for long-term success.

The PPR welding machine is a specialized tool used primarily for joining polypropylene random copolymer (PPR) pipes. These pipes are commonly used in plumbing systems for water supply and heating applications due to their strength, durability, and resistance to high temperatures and pressures. PPR pipes have become a standard in modern plumbing because they offer a combination of reliability and efficiency, making them a preferred choice for both residential and commercial projects.

Why Plumbers Need a PPR Welding Machine

Durability and Reliability

A PPR welding machine is essential for any plumber who wants to ensure that their work is both durable and reliable. The fusion process creates a joint that is stronger than the pipe itself, reducing the likelihood of leaks or failures. This reliability is crucial for maintaining customer satisfaction and building a strong reputation in the plumbing industry. Furthermore, by ensuring that each joint is as robust as the pipe material itself, plumbers can offer warranties on their work, giving customers added peace of mind.

Moreover, with increasing regulatory standards and consumer expectations, the demand for durable plumbing solutions is higher than ever. The use of a PPR welding machine aligns with these standards, providing a solution that not only meets but often exceeds industry requirements. For plumbers, this means fewer call-backs and repairs, saving time and resources in the long run.

Efficiency and Speed

Using a PPR welding machine can also significantly increase the efficiency and speed of your work. Traditional methods of joining pipes, such as using adhesives or mechanical fittings, can be time-consuming and prone to errors. With a PPR welding machine, you can achieve a perfect weld in a matter of minutes, allowing you to complete projects faster and take on more jobs. This efficiency translates into higher productivity and profitability for plumbers, as they can handle more projects within the same timeframe.

Additionally, the ease of use of modern PPR welding machines means that even those new to the trade can quickly become proficient in their operation. This accessibility helps in training new staff, ensuring that your team can maintain high standards of work across all projects. As a result, plumbing businesses can scale more effectively, taking on larger projects with confidence.

Versatility

PPR welding machines are versatile tools that can be used with a variety of pipe sizes and types. Whether you’re working with residential water systems or large-scale commercial installations, a PPR welding machine can handle the job. This versatility makes it an invaluable tool for any plumber looking to expand their service offerings. By being able to accommodate different pipe sizes and systems, plumbers can adapt to the varying demands of different projects without needing multiple specialized tools.

Moreover, the adaptability of the PPR welding machine means that plumbers can work on a wider range of projects, from small home repairs to major industrial installations. This broadens the scope of potential business opportunities, allowing plumbers to diversify their services and increase their market reach.

Key Features of a Professional PPR Welding Machine

When selecting a PPR welding machine, there are several key features to consider that will ensure you get the best tool for your needs. Investing in the right machine will not only enhance your work quality but also improve safety and efficiency on the job site.

Temperature Control

One of the most important features of a PPR welding machine is its ability to control temperature accurately. The machine should allow you to adjust the temperature settings to match the specifications of the pipes you are working with. This precision helps prevent overheating, which can weaken the joint, and underheating, which can result in a poor weld. Advanced machines come with digital displays and preset settings, making it easy to select the right temperature for different materials and conditions.

Additionally, consistent temperature control ensures that each weld is uniform, reducing the risk of weak points that could compromise the system’s integrity. This feature is particularly important when working with different types of PPR pipes, as varying thicknesses and compositions may require specific heat settings for optimal results.

Safety Features

Safety should always be a top priority when working with any type of welding equipment. A good PPR welding machine will include features such as insulated handles, automatic shut-off, and thermal protection to prevent overheating. These features help protect both the user and the equipment from damage. Machines with built-in safety mechanisms not only protect you from potential hazards but also ensure the longevity of the equipment, reducing the need for frequent repairs or replacements.

Furthermore, modern machines often come equipped with additional safety features like non-slip grips and warning indicators. These features provide an extra layer of security, ensuring that even in the busiest job sites, safety is never compromised. As a responsible plumber, investing in a machine with robust safety features is a testament to your commitment to safe and high-quality work.

Portability

For plumbers who frequently work on-site, a portable PPR welding machine is a must-have. Look for a compact, lightweight model that is easy to transport and set up, so you can take it wherever your work takes you. Portability is especially important for those who work on diverse projects, as it allows for quick transitions between job sites without the hassle of heavy, cumbersome equipment.

Moreover, a portable machine can be a game-changer for emergency repairs, where speed and mobility are critical. Being able to quickly set up and operate your welding machine can make a significant difference in resolving urgent issues efficiently. By choosing a model that balances portability with functionality, you ensure that you’re always prepared, no matter where the job takes you.

How to Use a PPR Welding Machine

Using a PPR welding machine requires some skill and practice, but with a few basic steps, you can achieve perfect welds every time. Mastering these steps ensures that each joint is secure and reliable, minimizing potential issues down the line.

- Preparation: Begin by cutting the PPR pipe to the desired length using a pipe cutter. Ensure that the cut is straight and clean, as this will affect the quality of the weld. Proper preparation also involves cleaning the pipe ends to remove any dust or debris that might interfere with the welding process. A clean, precise cut sets the foundation for a strong, seamless joint.

- Heating: Turn on the PPR welding machine and set the temperature according to the pipe’s specifications. Wait for the machine to reach the desired temperature, as indicated by the machine’s thermostat. Ensuring that the machine is at the correct temperature is crucial; too low, and the weld won’t form properly; too high, and you risk damaging the pipe material. Patience at this stage is key to achieving a successful weld.

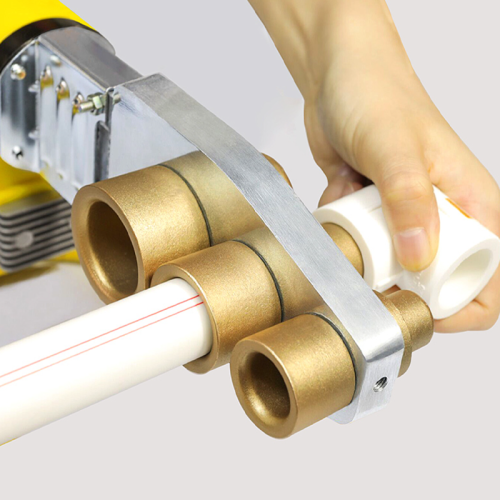

- Welding: Insert the ends of the pipe and fitting into the heating sockets of the machine. Hold them in place for the recommended heating time, usually a few seconds, until the material becomes soft and pliable. This step requires steady hands and attention to detail, as even a slight misalignment can affect the weld quality. Consistency in technique here will lead to better outcomes and fewer errors.

- Joining: Quickly remove the pipe and fitting from the machine and press them together, aligning them accurately. Hold them in place until the material cools and solidifies, forming a strong joint. Speed and precision are essential during this step to ensure that the joint sets correctly. Once aligned, maintaining steady pressure is important for achieving a uniform bond.

- Inspection: Once the joint has cooled, inspect it for any defects such as misalignment or incomplete fusion. A well-made weld should be uniform and free from gaps or bubbles. Regular inspection helps in identifying potential weak points early, allowing for corrections before the system is put into use. This proactive approach ensures long-term reliability and minimizes the risk of future leaks or failures.

Conclusion

The PPR welding machine is an indispensable tool for any plumber looking to improve the quality and efficiency of their work. With its ability to create strong, reliable joints quickly and easily, it is a valuable addition to any plumber’s toolkit. In an industry where precision and reliability are paramount, having a PPR welding machine at your disposal can set you apart from the competition.

By understanding the features and proper use of a PPR welding machine, you can ensure that your plumbing projects are completed to the highest standard. Whether you’re a seasoned professional or a newcomer to the trade, investing in a quality PPR welding machine will pay dividends in the quality and durability of your work. Embracing this technology not only enhances your craftsmanship but also positions you as a leader in modern plumbing solutions, ready to tackle any challenge that comes your way.