The safety and service life of PPR piping systems depend critically on fusion welding quality. Mastery of the following operational essentials is imperative:

- Precise Temperature Control (260℃±10)

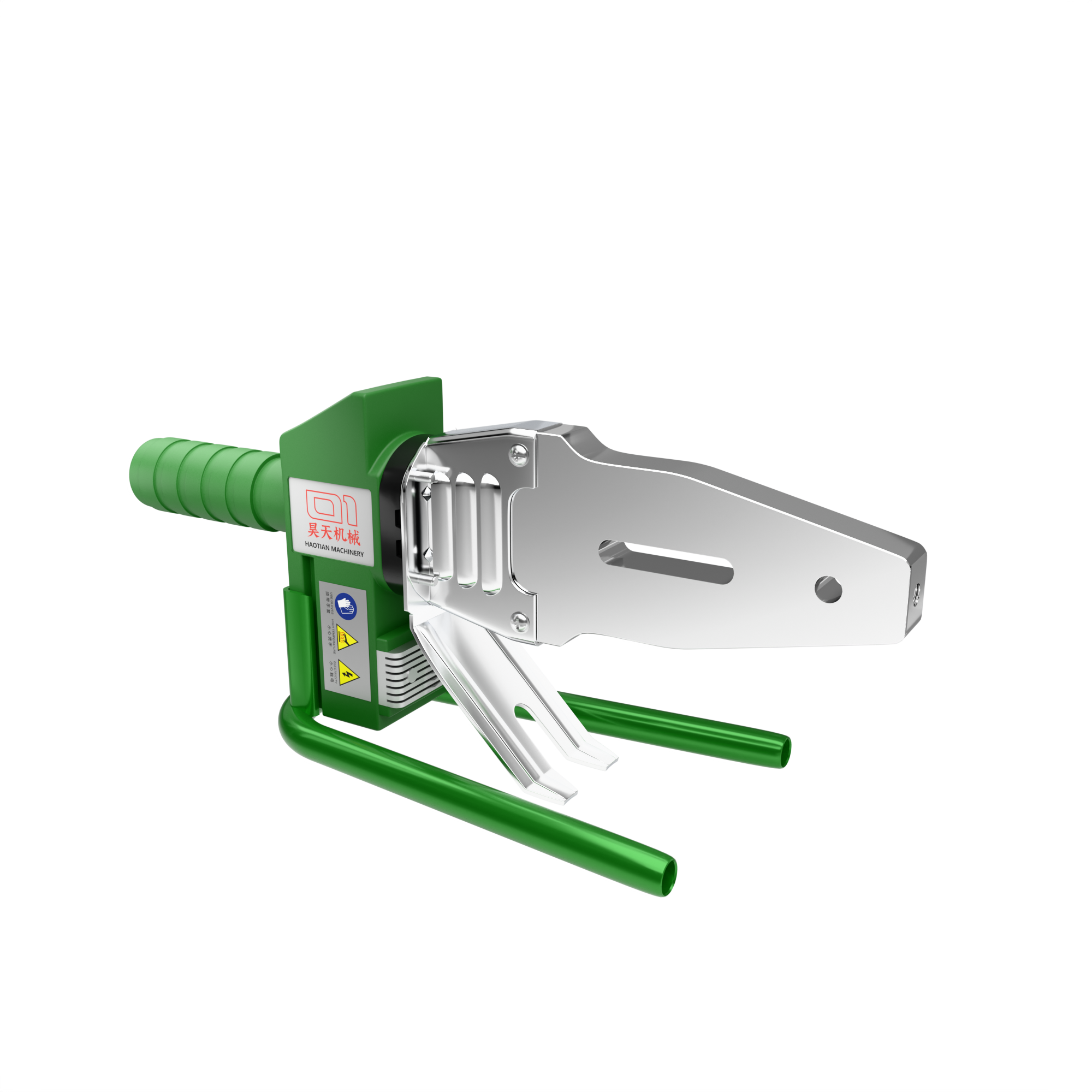

Meikang Piping Industry engineers warn: Adjustable fusion welders (PPR/PE dual-use, as shown below) pose significant risks due to temperature inaccuracy—- Overheating → Excessive liquefaction → Pipe end constriction (ID reduction ≥30%)

- Underheating → Incomplete fusion → Cold-joint delamination (70% higher leakage risk)

Conclusion: Strongly discourage using adjustable welders for PPR connections.

- Standardized Welding Depth

- Excessive depth: Material overflow → Flow path constriction

- Insufficient depth: Inadequate bonding → Pressure-bearing failure

Protocol: Follow depth standards by diameter (e.g., DN20 pipe=14.5±0.5mm)

- Accurate Heating DurationDiameter(mm)Heating(s)Tolerance205±0.5257±0.5328±0.5Overtime effect: Melt flow index surge → Constriction exceeding GB/T 18742.3 limit (≤5%)

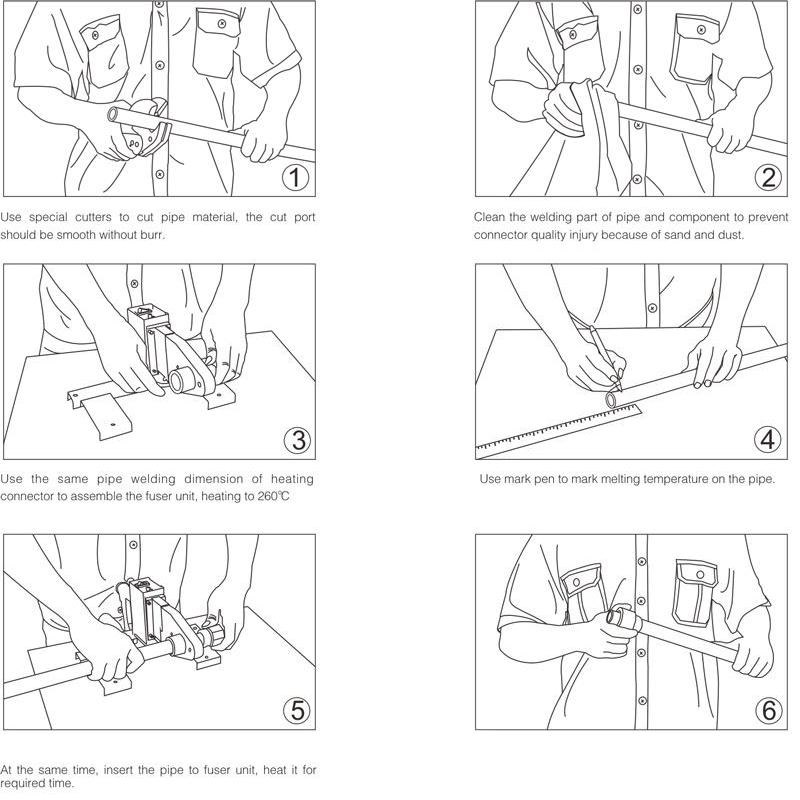

- Jointing Procedure

- Push aligned along horizontal axis (Speed ≤3mm/s)

- Pressure maintenance ≥5 seconds (Rotation PROHIBITED! Causes molecular chain disorientation)

Final Quality Assurance:

All welded systems must undergo hydrostatic testing (Test pressure=1.5×working pressure, duration ≥30 min) to eliminate micro-leakage defects.