Wybór właściwego Zgrzewarka do PPR is crucial for ensuring reliable and long-lasting pipe connections in plumbing and heating projects. With a wide range of models available, understanding how to compare PPR welding machine quality helps professionals, contractors, and distributors make smarter purchasing decisions.

1. What Is a PPR Welding Machine and Why Quality Matters

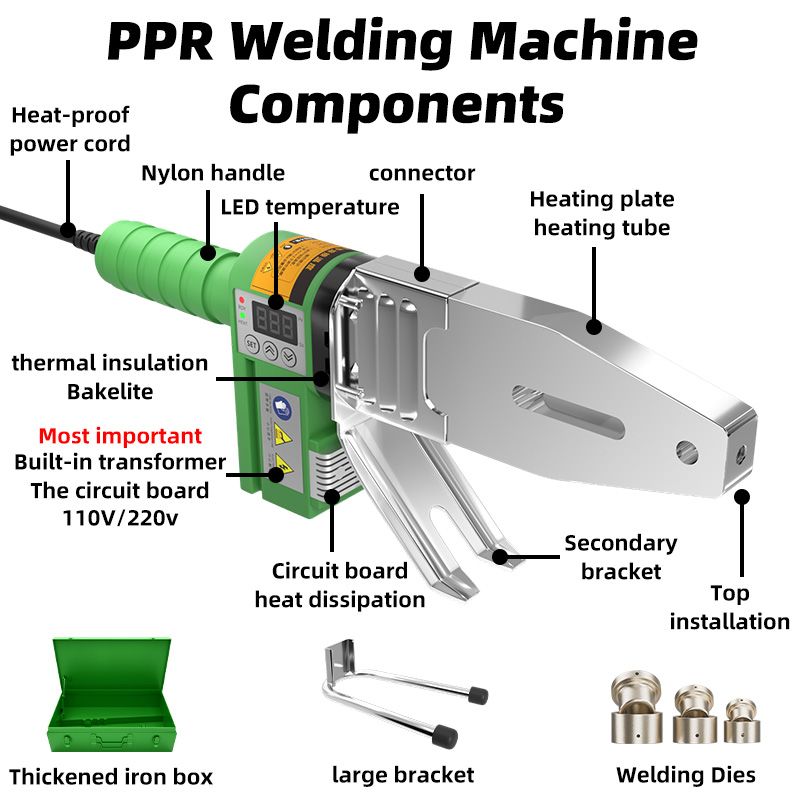

A Zgrzewarka do PPR, also known as a PPR pipe fusion machine, uses high heat to melt the ends of PPR pipes and fittings, fusing them into a seamless, leak-free connection.

High-quality machines ensure stable temperature control, durable performance, and precise operation — all of which directly affect the strength and longevity of the pipe system.

A premium machine provides:

- Accurate temperature control for clean fusion

- Long-term durability under heavy workloads

- Efficient heating and consistent output

Investing in a reliable PPR fusion welder means reduced downtime, consistent weld quality, and lower maintenance costs in the long run.

2. Core Comparison Factors of PPR Welding Machines

When evaluating Zgrzewarki do PPR, a professional buyer should look beyond appearance and focus on internal design and material quality.

Below are six key comparison points that define machine performance and overall build quality.

① Digital Display and Control System Comparison

Nowoczesny digital PPR welders feature temperature displays and precise adjustment systems.

- Digital control systems maintain ±1°C temperature accuracy, ensuring uniform heating and stable fusion.

- Analog dial machines are cheaper but often experience 10–20°C temperature drift, resulting in weak joints or pipe deformation.

For professional or export use, a digital temperature-controlled PPR welding machine is essential. It delivers precision, safety, and long-term reliability.

② Handle Material Comparison: Nylon vs. PP

Handle design directly affects comfort, heat resistance, and safety during operation.

- Nylon handles: Superior heat resistance, excellent grip, and high durability under continuous use.

- PP (Polypropylene) handles: Lightweight and economical but may deform or soften under high heat.

For professional use, nylon-handled welders are the industry standard for safety and longevity.

③ Heating Tube Quantity Comparison

The number of heating tubes directly affects heating speed and temperature stability.

- Single heating tube: The standard configuration for general welding tasks.

- Dual heating tubes: Faster heating speed, more uniform temperature distribution, and higher efficiency.

Dual-tube digital PPR welding machines ensure stable performance even during large-scale or long-term operations.PR welding machine ensures stable performance in large-scale or long-duration operations.

④ Heating Plate Thickness Comparison

Heating plate thickness determines thermal stability and energy retention.

- Thin plates (12–16mm): Heat up quickly but lose temperature easily; suited for light-duty use.

- Thick plates (16–22mm): Retain heat longer, offer steady temperature output, and improve welding consistency.

Select machines with thicker aluminum heating plates for industrial-grade projects requiring continuous operation.

⑤ Temperature Control System Comparison

Temperature precision defines weld quality.

- Mechanical thermostats: Low cost, but unstable and prone to fluctuation.

- Digital PID controllers: Continuously monitor and correct heat levels, ensuring every weld reaches optimal fusion temperature.

For professionals, digital PID-controlled systems guarantee stable heating, consistent joints, and reduced rework.

⑥ Welding Mold (Die Head) Comparison

The die headlub fusion mold, directly transfers heat to the PPR pipe and fitting — making it one of the most important quality indicators.

- Ordinary aluminum molds: Conduct heat well but wear and oxidize easily.

- Teflon-coated molds: Offer non-stick surfaces, reduce residue, and improve weld finish.

- Copper molds: Provide superior heat retention, corrosion resistance, and long lifespan.

For export or continuous production, choose Teflon-coated to ensure smooth operation and longer service life.

3. Additional Factors to Evaluate

Beyond core components, also consider:

- Ergonomic Design: Comfortable grip and balanced weight improve efficiency.

- Cable Quality: High-grade power cables resist heat and mechanical stress.

- Certifications: CE, ISO, or equivalent safety standards ensure international compliance.

Attention to these details guarantees long-term reliability and user safety.

4. Cost vs. Value: Making the Smart Investment

Don’t judge purely by price. A low-cost machine may have poor temperature stability, short lifespan, or unreliable components.

Instead, consider total value — combining performance, longevity,

High-quality cyfrowe zgrzewarki PPR deliver consistent results, reduce rework, and ensure greater return on investment (ROI).

5. Maintenance, Spare Parts, and After-Sales Support

Even the best PPR welding machine requires proper maintenance. Choose suppliers that offer:

- Readily available spare parts

- Detailed maintenance instructions and technical support

Routine inspection and cleaning help extend machine lifespan and maintain consistent performance.

6. Conclusion: Choosing the Best PPR Welding Machine

A superior Zgrzewarka do PPR combines:

Cyfrowa kontrola temperatury

Nylon handle design

Triple heating tubes

Thick heating plate

Precision die heads

By comparing these technical aspects, you can identify machines that deliver strong, clean, and durable joints.

HaoTian, a leading PPR welding machine manufacturer and exporter, provides advanced digital PPR welders engineered for international markets.

Each model is built for accuracy, stability, and longevity — meeting the needs of professional installers and distributors worldwide.