正しい選択 PPR溶接機 is crucial for ensuring reliable and long-lasting pipe connections in plumbing and heating projects. With a wide range of models available, understanding how to compare PPR welding machine quality helps professionals, contractors, and distributors make smarter purchasing decisions.

1. What Is a PPR Welding Machine and Why Quality Matters

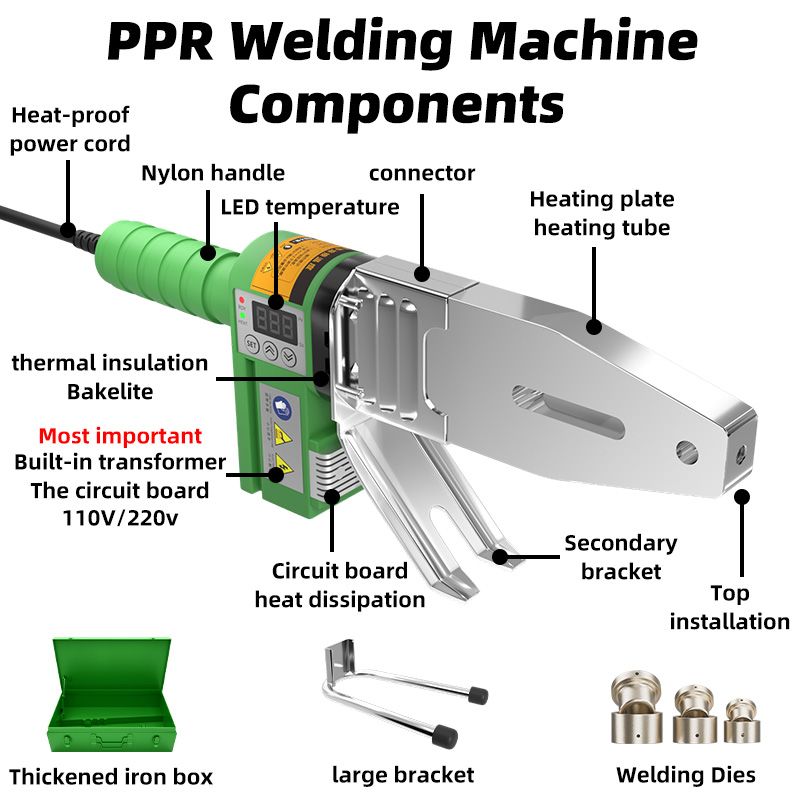

A PPR溶接機, also known as a PPR pipe fusion machine, uses high heat to melt the ends of PPR pipes and fittings, fusing them into a seamless, leak-free connection.

High-quality machines ensure stable temperature control, durable performance, and precise operation — all of which directly affect the strength and longevity of the pipe system.

A premium machine provides:

- Accurate temperature control for clean fusion

- Long-term durability under heavy workloads

- Efficient heating and consistent output

Investing in a reliable PPR fusion welder means reduced downtime, consistent weld quality, and lower maintenance costs in the long run.

2. Core Comparison Factors of PPR Welding Machines

When evaluating PPR溶接機, a professional buyer should look beyond appearance and focus on internal design and material quality.

Below are six key comparison points that define machine performance and overall build quality.

① Digital Display and Control System Comparison

モダン digital PPR welders feature temperature displays and precise adjustment systems.

- Digital control systems maintain ±1°C temperature accuracy, ensuring uniform heating and stable fusion.

- Analog dial machines are cheaper but often experience 10–20°C temperature drift, resulting in weak joints or pipe deformation.

For professional or export use, a digital temperature-controlled PPR welding machine is essential. It delivers precision, safety, and long-term reliability.

② Handle Material Comparison: Nylon vs. PP

Handle design directly affects comfort, heat resistance, and safety during operation.

- Nylon handles: Superior heat resistance, excellent grip, and high durability under continuous use.

- PP (Polypropylene) handles: Lightweight and economical but may deform or soften under high heat.

For professional use, nylon-handled welders are the industry standard for safety and longevity.

③ Heating Tube Quantity Comparison

The number of heating tubes directly affects heating speed and temperature stability.

- Single heating tube: The standard configuration for general welding tasks.

- Dual heating tubes: Faster heating speed, more uniform temperature distribution, and higher efficiency.

Dual-tube digital PPR welding machines ensure stable performance even during large-scale or long-term operations.PR welding machine ensures stable performance in large-scale or long-duration operations.

④ Heating Plate Thickness Comparison

Heating plate thickness determines thermal stability and energy retention.

- Thin plates (12–16mm): Heat up quickly but lose temperature easily; suited for light-duty use.

- Thick plates (16–22mm): Retain heat longer, offer steady temperature output, and improve welding consistency.

Select machines with thicker aluminum heating plates for industrial-grade projects requiring continuous operation.

⑤ Temperature Control System Comparison

Temperature precision defines weld quality.

- Mechanical thermostats: Low cost, but unstable and prone to fluctuation.

- Digital PID controllers: Continuously monitor and correct heat levels, ensuring every weld reaches optimal fusion temperature.

For professionals, digital PID-controlled systems guarantee stable heating, consistent joints, and reduced rework.

⑥ Welding Mold (Die Head) Comparison

について die headあるいは fusion mold, directly transfers heat to the PPR pipe and fitting — making it one of the most important quality indicators.

- Ordinary aluminum molds: Conduct heat well but wear and oxidize easily.

- Teflon-coated molds: Offer non-stick surfaces, reduce residue, and improve weld finish.

- Copper molds: Provide superior heat retention, corrosion resistance, and long lifespan.

For export or continuous production, choose Teflon-coated to ensure smooth operation and longer service life.

3. Additional Factors to Evaluate

Beyond core components, also consider:

- Ergonomic Design: Comfortable grip and balanced weight improve efficiency.

- Cable Quality: High-grade power cables resist heat and mechanical stress.

- Certifications: CE, ISO, or equivalent safety standards ensure international compliance.

Attention to these details guarantees long-term reliability and user safety.

4. Cost vs. Value: Making the Smart Investment

Don’t judge purely by price. A low-cost machine may have poor temperature stability, short lifespan, or unreliable components.

Instead, consider total value — combining performance, longevity,

High-quality デジタルPPR溶接機 deliver consistent results, reduce rework, and ensure greater return on investment (ROI).

5. Maintenance, Spare Parts, and After-Sales Support

Even the best PPR welding machine requires proper maintenance. Choose suppliers that offer:

- Readily available spare parts

- Detailed maintenance instructions and technical support

Routine inspection and cleaning help extend machine lifespan and maintain consistent performance.

6. Conclusion: Choosing the Best PPR Welding Machine

A superior PPR溶接機 combines:

デジタル温度制御

Nylon handle design

Triple heating tubes

Thick heating plate

Precision die heads

By comparing these technical aspects, you can identify machines that deliver strong, clean, and durable joints.

ハオティアン, a leading PPR welding machine manufacturer and exporter, provides advanced digital PPR welders engineered for international markets.

Each model is built for accuracy, stability, and longevity — meeting the needs of professional installers and distributors worldwide.