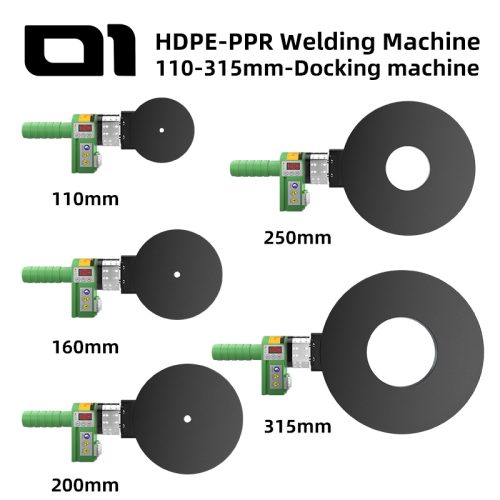

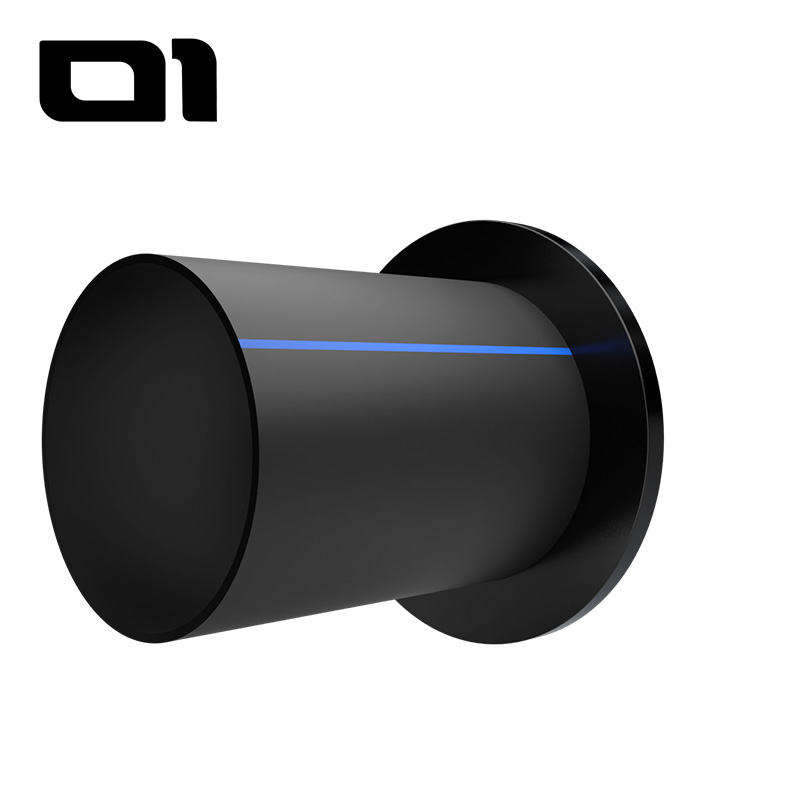

handheld HDPE fusion machine allows technicians to perform butt welding directly in the field without clamps, stands, or support frames. The heating plate is coated with non-stick Teflon, and the temperature can be precisely adjusted from 55°C to 340°C, making it suitable for various HDPE pipe thicknesses. This tool is lightweight, easy to operate, and available in multiple diameter options: 110 / 160 / 200 / 250 / 315 mm.

Unlike traditional hydraulic fusion equipment, the handheld design enables welding in trenches, rooftops, and confined areas where positioning large machinery is impossible.

1. Preparation Before Using the HDPE Butt Machine

Before starting butt welding, complete basic preparation to ensure a clean and strong fusion joint.

- Cut the pipe ends straight.

Use a pipe cutter or saw to create a flat, clean pipe end — angle cuts weaken the joint. - Clean the pipe ends.

Remove dust, sand, mud, grease, or moisture. Contamination will cause a weak weld. - Set proper temperature.

Adjust the digital thermostat on the machine:

55–340°C (HDPE normally around 200–220°C depending on pipe spec). - Confirm safety measures.

Wear gloves and eye protection. Keep the heating surface away from flammable materials.

2. Butt Welding Process (Direct HDPE Fusion)

Follow the correct welding sequence to achieve a strong, permanent joint.

Step-by-step operation

Step 1 — Heat the pipe ends

Place both pipe ends against the Teflon-coated heating plate.

No support clamps are needed — handheld pressure is sufficient.

Step 2 — Form the molten bead

Hold until a uniform molten bead appears on both pipe edges.

Step 3 — Remove heating plate

Quickly remove the HDPE fusion machine from between the pipes.

Step 4 — Press to fuse

Press both melted pipe ends together and maintain steady pressure.

Hold still until the joint cools and solidifies.

Result: The two pipes become one continuous piece — no leaks.

3. Socket Welding Mode (HDPE/PPR Fittings)

This handheld fusion machine can also operate as a Socket welding tool.

Simply install the socket molds, and it can weld:

- HDPE fittings

- PPR fittings

Operation steps for socket welding:

- Install the correct socket mold size on the heating plate.

- Insert pipe and fitting into the mold simultaneously.

- Wait until the molten layer forms.

- Remove and push the pipe into the fitting.

- Hold until cooled.

One machine = butt welding + socket welding, depending on configuration.

4. Temperature and Heat Quality Control

- Precision thermostat ensures stable temperature (55–340°C)

- Teflon surface prevents melted plastic from sticking

- High-temperature power cable ensures continuous safe heating

No scraping or cleaning after welding — the surface stays clean.

5. Inspection and Quality Confirmation

A correct butt weld should show:

- Smooth and symmetrical external bead

- No visible gaps

- No burnt or charred areas

If any defect appears, cut and redo the weld. HDPE fusion is permanent — don’t compromise quality.

Common Mistakes to Avoid

| Issue | Cause | Fixer |

|---|---|---|

| Weak joint | Contaminated surface | Always clean before welding |

| Irregular bead | Insufficient heat | Increase temperature or heat time |

| Pipes misaligned | Hand pressure unstable | Apply steady pressure when fusing |

Conclusion

Using a handheld HDPE butt machine is simple, fast, and efficient:

- Heat → Align → Press → Hold until cooled

It delivers professional results without bulky fusion equipment.

Whether doing butt welding ou Socket welding, this handheld HDPE fusion machine gives contractors a flexible solution for field installations.