Welding in cold weather is not simply a temperature problem—it directly affects fusion quality, heating stability and joint durability. For industries using PPR, HDPE, PP-RCT, PE-RT and industrial plastic pipe systems, low temperatures can lead to brittle failures, incomplete melting, moisture contamination and unnecessary rework. That’s why thicker fusion welding machines, also referred to as heavy-duty cold-weather PPR welding equipment, are widely preferred by professional installers and contractors working in winter and outdoor environments.

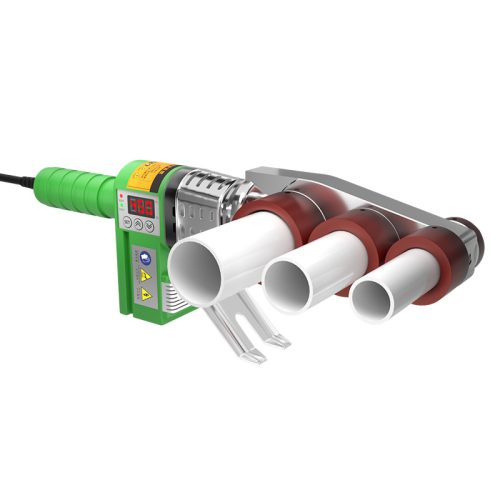

Unlike standard lightweight welders, thicker fusion welding machines offer stronger insulation, more accurate temperature control and faster heating efficiency. These advantages make them significantly more reliable for winter pipe welding projects.

The Real Challenges of Fusion Welding in Cold Weather

When ambient temperatures drop, installers face several unavoidable problems:

1. Heat Loss During Welding

Cold air quickly draws heat away from the socket fusion head or heating die. As soon as the pipe contacts the surface, temperature can drop instantly, leading to half-melted joints and weak bonding.

2. Brittle Materials and Cracking Risk

PPR and HDPE become less flexible in cold weather. Without sufficient surface melting, inserting the pipe can cause stress cracks or internal tension that later results in leaks or deformation.

3. Moisture Contamination

Frost, condensation or snow can interfere with the fusion surface, preventing proper bonding and reducing the long-term durability of the welded connection.

4. Uneven or Delayed Cooling

Slow heat recovery and unstable temperature output often produce invisible internal defects that only appear during pressure testing or actual use.

These issues occur frequently in municipal construction, pipeline installation, building heating systems, cold storage projects, rural water supply, mountain construction zones and open-air job sites.

How Thicker Fusion Welding Machines Fix These Cold-Weather Problems

1. Superior Heat Retention & Insulation

Thicker fusion welding machines are designed with reinforced heating plates and high-density aluminum or brass dies. The extra thermal mass allows the weld head to retain heat longer, reducing the impact of wind, frost and ambient temperature.

2. More Accurate Temperature Control

Temperature fluctuation is one of the main causes of welding defects in winter. Thicker machines feature enhanced thermostats or digital controllers that maintain stable heating and allow a 10–20°C increase when needed. This ensures full molecular fusion without overheating or under-melting.

3. Higher Fusion Efficiency in Low Temperatures

Because thicker machines recover heat faster and lose less energy, welders don’t have to wait between joints. This directly improves productivity, reduces downtime and eliminates rework caused by insufficient melting.

建议长尾词:

fast-recovery fusion welder, high-efficiency winter pipe welding machine

4. Better Performance for Large-Diameter and Thick-Wall Pipes

In cold-weather installations, thicker pipe walls require stronger and more stable heat. Heavy-duty fusion welders ensure deeper, even melting for pipes ranging from 20mm up to 160mm or more without heat collapse or uneven bonding.

5. Longer Service Life and Fewer Breakdowns

Thicker fusion welding machines are built with durable internal components, cold-resistant power cables and anti-deformation housings. This minimizes temperature shock damage, sensor malfunction and heat drop failures.

Where Thicker Fusion Welding Machines Are Most Effective

Professionals choose thicker machines when working in:

- Outdoor winter pipeline installation

- PPR hot and cold water systems in low temperatures

- HDPE drainage and municipal engineering

- HVAC and insulation projects

- Construction sites without indoor heating

- High-altitude or windy environments

- Industrial and agricultural piping in subzero areas

In these jobs, using a lightweight fusion machine often leads to poorly bonded joints, cracking, leaks and expensive repairs.

Final Conclusion

In low-temperature or outdoor construction environments, the quality of each welded joint depends heavily on the equipment used. Thicker fusion welding machines provide a decisive advantage thanks to their stronger insulation performance, precise heating control and higher melting efficiency.

Compared to standard welders, they offer:

- Longer heat retention and minimal temperature loss

- Stable fusion temperature even in freezing conditions

- Faster heating cycles and improved job-site efficiency

- Reduced cracking, contamination and rework

- Better performance on larger or thicker pipes

- Higher safety, durability and sealing performance

For contractors, pipe installers and engineering teams, investing in a thicker fusion welding machine is not only an equipment upgrade—it’s the key to preventing winter weld failures and ensuring consistent quality across every project.