Introduction

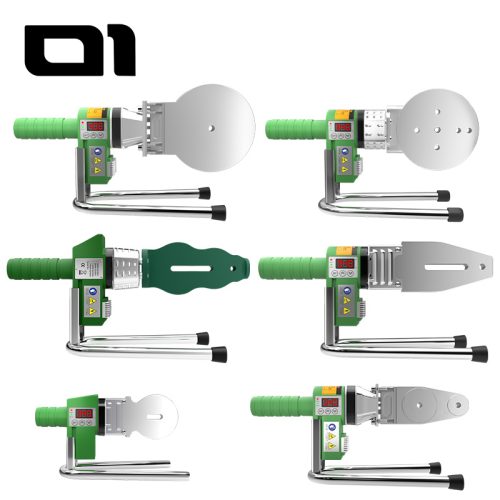

PPR welding machines are essential for achieving durable and leak-proof connections in modern plumbing systems. While power and temperature control are often considered first, the heating plate specifications—including size, thickness, and material—are the most critical factors influencing welding quality, efficiency, and the service life of both the machine and the pipe system.

Heating Plate Size: Matching Pipe Diameter and Project Scale

The size of the heating plate determines the maximum pipe diameter the welding machine can handle.

– Small heating plates (20–32 mm): Designed for micro-diameter piping, typically used in household plumbing repairs, heating systems, and compact projects where space is limited. They are extremely portable, heat up quickly, and allow precision work on delicate connections.

– Compact plates (20–63 mm): Lightweight and versatile, ideal for general household plumbing, small commercial installations, or on-site repairs.

– Medium heating plates (63–110 mm): Provide a balance between portability and functionality, suited for residential complexes or medium commercial projects.

– Large heating plates (110–160 mm and above): Built for industrial applications where larger PPR or HDPE pipes are used. These plates deliver stable heating and uniform fusion across large diameters.

Heating Plate Thickness: Stability and Heat Retention

While diameter defines compatibility, thickness directly affects heat stability and durability.

– Thin plates (≤12 mm): Heat up quickly but lose temperature faster. Suitable for short, frequent welds in small projects.

– Medium thickness plates (10–15 mm): Offer better thermal stability and reduce temperature fluctuations during multiple welds.

– Thick plates (15–20 mm+): Provide superior heat retention and uniform distribution, essential for industrial-scale welding of large pipes.

Engineering note: A thicker plate reduces the risk of overheating edges while keeping the central zone stable, ensuring consistent fusion quality.

Heating Power and Wattage

The size and thickness of the heating plate must be supported by adequate wattage:

– Small plates (≤63 mm): Typically paired with 800–1000 W heating elements.

– Medium plates (63–110 mm): Require 1200–1500 W for stable operation.

– Large plates (≥160 mm): Often demand 1800 W or more to maintain constant fusion temperature.

Undersized wattage for a large plate leads to slow heating, inconsistent fusion, and reduced productivity.

Temperature Control and Precision

Regardless of plate size or thickness, precise temperature control (260 ℃ ±10) is non-negotiable.

– Machines with digital thermostats ensure accuracy across large heating plates.

– Analog or adjustable dual-use welders may cause overheating or underheating, leading to constriction or cold joints.

Conclusion

When selecting a PPR welding machine, prioritize the heating plate specifications over general machine size.

– Diameter (20–160 mm) defines which pipes can be welded.

– Thickness (12–20 mm) influences heat stability and fusion quality.

– Material and coating impact durability, safety, and ease of use.

– Power and control systems must align with plate dimensions to deliver consistent performance.

By carefully evaluating heating plate size, thickness, and material, professionals can ensure efficient, durable, and standardized PPR pipe installations across any project scale.