Introduction

In PPR, PE, and HDPE pipeline welding, a fusion welding machine (PPR fusion welder) is the key tool to ensure strong and durable connections. To maximize performance and extend service life, it is essential to understand each component and its role. This article provides a detailed breakdown of HaoTian fusion welder parts, helping users achieve safer, more efficient welding operations.

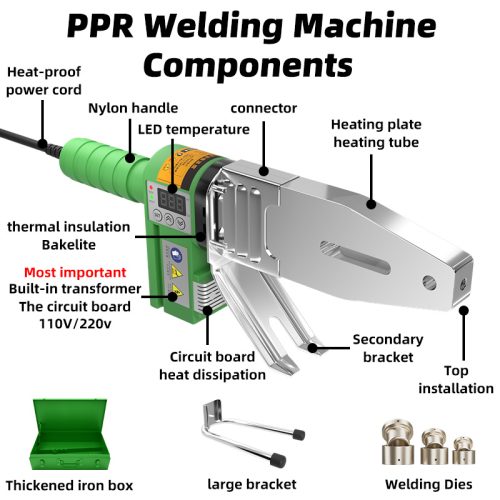

1. Overview of Main Components

A professional PPR fusion welder typically includes:

- Frame & Base Support

- Control System (Independent PCB / Temperature Controller / Transformer)

- Heating Elements (Heating Plate & Ceramic Core Heating Tube)

- Welding Dies (with Teflon Coating)

- Chip Heat Sink

- Power Cord (Heat-resistant cable)

- Display & Operation Panel (LED digital screen & buttons)

- Nylon Outer Shell

2. Detailed Component Functions

2.1 Control System (Independent PCB, Temperature Controller & Transformer)

- Function: Core control and precise temperature regulation.

- Features: HaoTian’s independently developed circuit board ensures ±1°C accuracy with memory function, supporting both 110V and 220V. It provides stable power supply and long-term reliability, making it ideal for global users.

2.2 Heating Elements

Heating Plate

- Function: Provides uniform surface heating for welding dies.

- Features: Made of high-grade aluminum, ensuring stable and even heat distribution.

Ceramic Core Heating Tube

- Function: Acts as the internal heating source for rapid temperature rise.

- Features: Built with a ceramic heating core, it offers faster heating, stable temperature output, and longer lifespan compared to traditional resistance wires. High energy efficiency reduces power consumption while maintaining excellent performance.

2.3 Welding Dies (Sockets with Teflon Coating)

- Function: Accommodates multiple pipe diameters (Φ20–160mm).

- Features: Interchangeable, wear-resistant, with non-stick Teflon coating that prevents pipe blockage, provides fast heat transfer, and ensures smooth welding.

2.4 Chip Heat Sink

- Function: Ensures stable operation of the circuit board and control chips.

- Features: Made of aluminum alloy, it effectively dissipates heat, prevents overheating, and extends the lifespan of electronic components.

2.5 Power Supply & Cables

- Function: Provides safe and continuous power.

- Features: Premium copper-core power cord with heat-resistant coating for durability and operator safety.

2.6 Outer Shell & Frame

- Function: Protection and operator comfort.

- Features: High-strength nylon shell with insulation and anti-scald design, ensuring both safety and ergonomic handling.

2.7 Display & Operation Panel (LED Digital Display / Buttons)

- Function: Displays temperature and working status in real time.

- Features: Easy to operate, allowing intuitive control with accurate temperature monitoring.

3. Accessories & Extensions

- Heavy-duty Tool Box: For easy portability and protection.

- Support Stand: Provides stable working platform.

- Replacement Welding Dies: Supports multiple pipe diameters.

4. Conclusion

Every component of a HaoTian fusion welder is carefully engineered to deliver long-lasting, professional results:

- Ceramic Core Heating Tube enables rapid heating and stable temperature control.

- Independent PCB (Self-developed) ensures precision, reliability, and global compatibility.

- Teflon-coated Welding Dies guarantee smooth fusion and prevent pipe sticking.

- Efficient Heat Dissipation System protects electronic parts for extended service life.

With over 20 years of expertise, HaoTian continues to provide high-quality, innovative, and durable fusion welding solutions for global pipeline infrastructure.