Haotian PPR welding machine not only outputs temperature, but also delivers deliverable welding results and long-term trust. We will directly integrate safety tips and operating procedures into the device itself, strengthen awareness with labels, and ensure results with design. Every icon and every prompt you see is the accumulation of manufacturing standards and on-site experience

Engineering Safety: Where Labels Matter

Key safety icons—for gloves, high temperature, and electrical hazards—are placed in critical, highly visible positions. This visual vigilance is backed by superior hardware design:

- Insulated Housing & Handles: Significantly reducing the risk of burns from hot surfaces.

- Compliant Internal Wiring: All internal circuitry and cable routing meet international safety standards, actively minimizing electrical hazards.

- Clear Visual Cues: These on-device reminders reduce operator error on-site, leading to fewer accidents and fewer warranty claims.

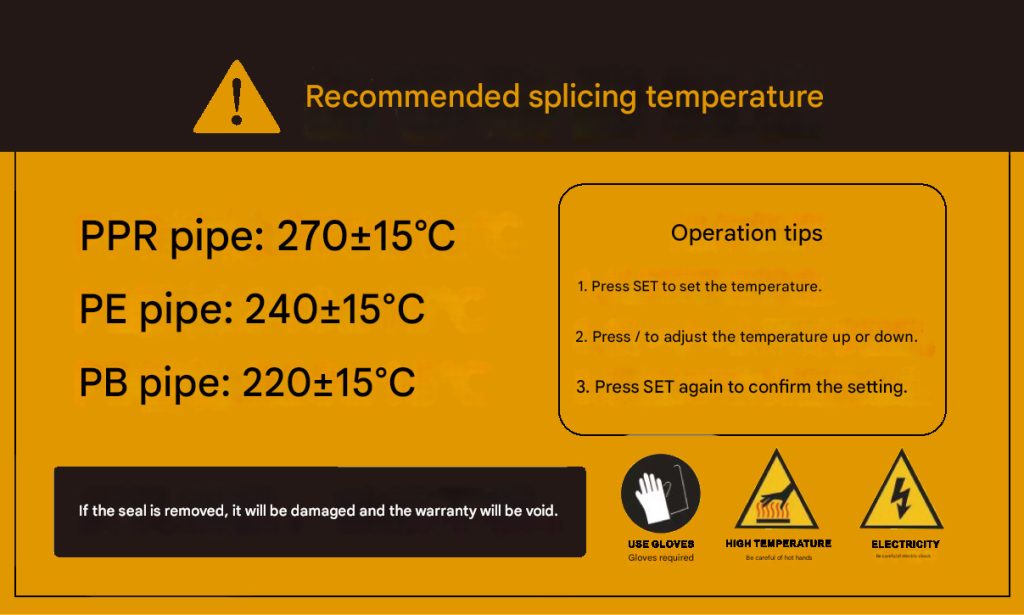

Precision Temperature Control: Matching Material to Result

The device’s digital controller supports the recommended fusion temperature range for various polymers, ensuring an optimal melt for molecular fusion:

| Polymer | Recommended Fusion Temperature |

| PPR (Polypropylene Random Copolymer) | 270±15 ∘C |

| PE (Polyethylene) | 240±15 ∘C |

| PB (Polybutene) | 220±15 ∘C |

These settings aren’t arbitrary—they reflect the precise melting characteristics of each polymer. Our controller keeps the temperature stable within the specified band, allowing each joint to achieve the correct melt flow and molecular fusion. This precision minimizes instances of weak joints and post-installation leaks.

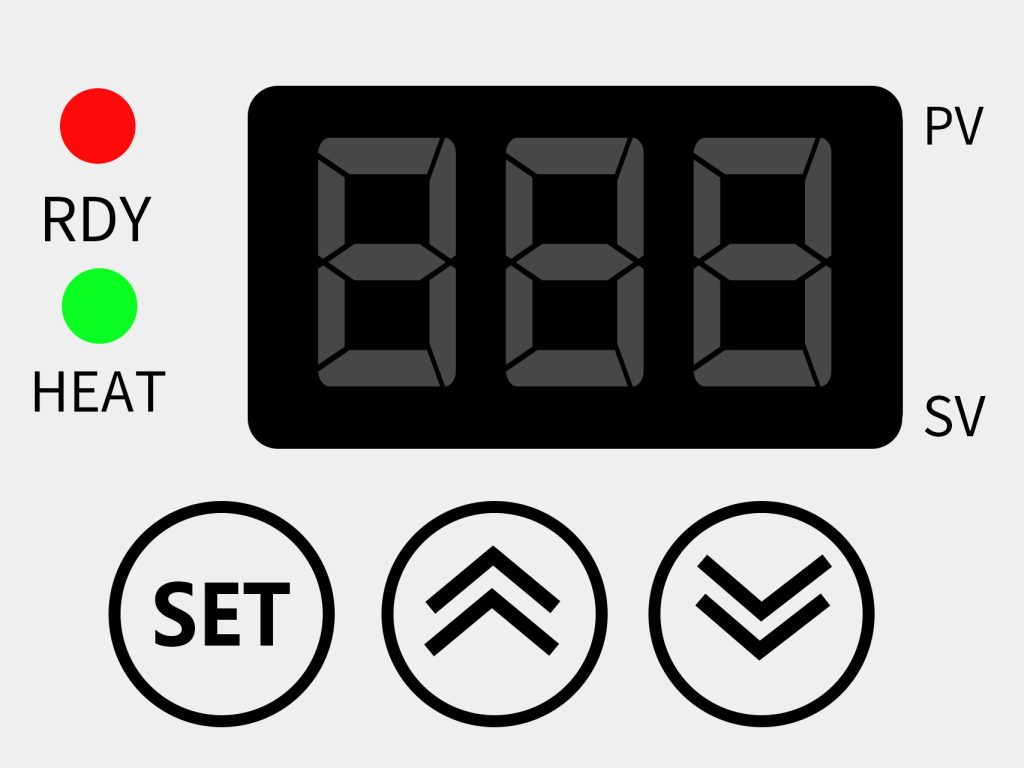

Operation Designed for Consistency: Precise Control, Simplified Workflow

We recognize that most joint failures stem from operator error, not hardware malfunction. That’s why we engineered the Haotian PPR Welding Machine not only for precision but also for simplicity.

The digital controller allows the operator to quickly and accurately dial in the exact required temperature for a given polymer (PPR, PE, or PB) using the simplified onboard prompts: SET → ▲/▼ → SET.

This optimized workflow is designed to:

- Ensure Perfect Fusion: By providing a stable, precisely controlled temperature, the system takes the guesswork out of heating, ensuring the material reaches the ideal melt flow for a superior molecular bond and stronger joint.

- Minimize Operator Error: Intuitive controls drastically reduce the chance of missetting the temperature—the single greatest cause of poor weld quality.

- Reduce Reliance on Operator Experience: Repeatable, temperature-perfect cycles guarantee repeatable, high-strength joints. Even a novice plumber can easily achieve a perfect, leak-proof weld with the assurance of professional quality.

- Increase Project Efficiency: Minimize setup time, shorten preheat cycles, and virtually eliminate joint failures, leading to a substantial reduction in project rework and expensive

- callbacks.

A Commitment to Safe Operation

Our labels are not just stickers; they represent a serious commitment to product safety. These warnings and instructions directly alert Haotian PPR Welding Machine users, ensuring safer operation and effectively guiding new operators toward standardized procedures. This intense focus on compliance and safety is the core of our product’s value proposition: safer operation,

- Fewer On-Site Failures and Warranty Incidents: The labeled safety and operational guides minimize human error and accidents.

- Greater Confidence in Commercial and Export Projects: Our Design for Compliance philosophy ensures the machine gains stronger acceptance in demanding commercial projects and international export markets.

- Higher Installation Efficiency and Lower Labor Costs: The machine’s ease of use and consistent, high-quality results reduce training time and mitigate the risks associated with novice operation.