Most PPR pipe fusion welding problems are caused by poor welding. Welding quality is a crucial step in PPR pipe installation. We’ve previously discussed the proper welding procedures for PPR pipes, and every pipe installer should strictly adhere to them.

Let’s look at a standard welding

- A correctly welded PPR pipe and fitting will:

- Be fully fused without gaps

- Show uniform melting around the joint

- Have no burn marks, bubbles, or deformation

- Form a seamless and leak-free connection

Standard PPR water pipe welding, pipes and fittings are fully integrated

Let’s look at some common welding problems:

Soldering temperature is too high

When the welding temperature exceeds the recommended level, the material becomes too soft or even carbonizes. This leads to:

- Weak bonding

- Internal shrinkage

- Surface scorching

- Pipe deformation

PPR pipe welding socket is not in place

When the welding temperature exceeds the recommended level, the material becomes too soft or even carbonizes. This leads to:

- Weak bonding

- Internal shrinkage

- Surface scorching

- Pipe deformation

- Hidden cracks and future leaks

The welding machine temperature is too high

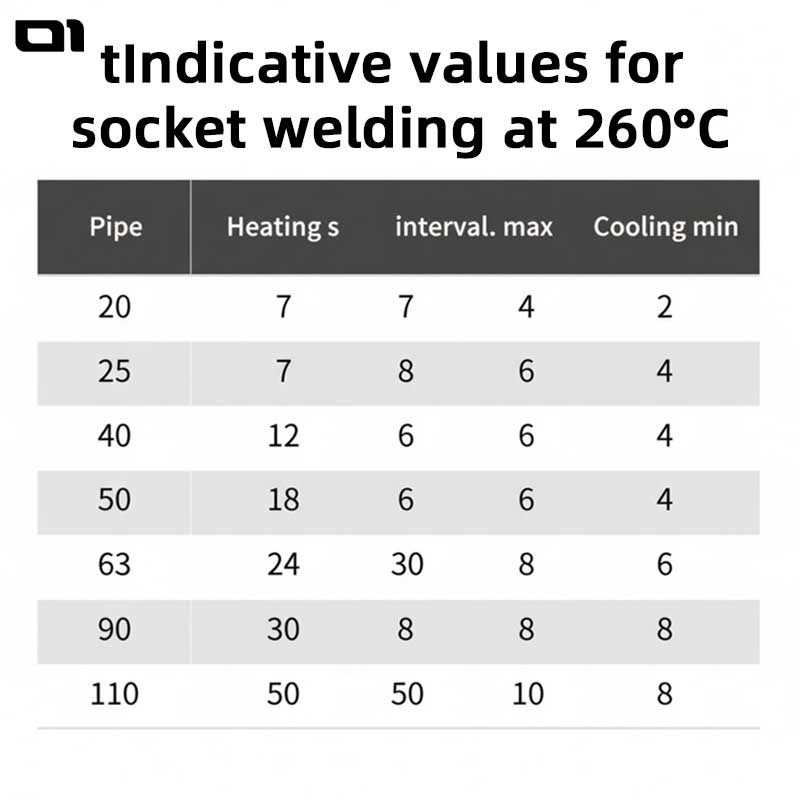

We recommend using standard welding temperatures for PPR pipes and fittings. If thermostatic welding is used, the PPR welding temperature should be 260°C (preferably no higher than 300°C) according to welding specifications. Excessively high temperatures can cause the PPR material to become too soft and even partially carbonize, leading to welding problems.

Socket welding mold aging damage

The welding die on the hot melt welding machine for PPR pipes uses Teflon coating. Teflon has low surface energy, so the melted PPR will not stick to it. However, under long-term high temperature environment, Teflon as a polymer material will also age, which will not prevent PPR from sticking. Many plumbers do not clean the die head when welding PPR water pipes, and they do not have the habit of regularly replacing the welding die head, which makes it difficult to ensure the welding quality of PPR water pipes.

How to Prevent Mold-Related Welding Failures:

- Clean die surfaces regularly

- Replace aged or peeling dies in time

- Avoid overheating the tool when idle

- Use certified Teflon-coated heads

- Match the die size to the pipe diameter

Improve the quality of welded PPR pipes

Welding skills are essential for consistently secure, leak-free joints—but using a reliable PPR fusion machine can significantly improve precision, temperature stability, and work efficiency. Many PPR pipe fusion welding problems stem not from the pipe itself, but from unstable heat output, worn dies, or inaccurate temperature control. If you’re looking to improve weld quality or upgrade older equipment, choosing a professional-grade PPR fusion machine with precise constant temperature control, durable Teflon-coated dies, and multi-diameter brackets can significantly reduce failure rates and improve field performance. A well-designed tool can’t replace skill—but it can help a skilled plumber complete PPR installations faster, cleaner, and more reliably.