Fusion welding machines have become an indispensable tool in various industries, offering precision, efficiency, and versatility. These machines are crucial for sectors ranging from construction to manufacturing, providing reliable solutions for joining materials like high-density polyethylene (HDPE) pipes or metal components. By understanding the advantages of fusion welding machines, one can appreciate their essential role in modern engineering and construction.

Overview of the Fusion Welding Process

Fusion welding is a process where two pieces of material are joined together using heat. This process can be accomplished through different methods such as socket fusion, butt fusion, and electric fusion. Each method has its unique applications and benefits, making fusion welding machines highly adaptable to various needs. The adaptability of these machines is a key factor in their widespread adoption across diverse industrial application

Fusion welding is not just about joining materials; it’s about doing so with precision and reliability. Different fusion methods cater to specific industrial requirements, ensuring that the right technique is available for each unique application. Whether it’s ensuring a leak-proof seal in plumbing systems or creating robust joints in metal structures, fusion welding machines offer solutions that are both effective and efficient.

Types of Fusion Welding Machines

Before diving into the advantages, let’s briefly cover the primary types of fusion welding machines:

Socket Fusion Welding Machine

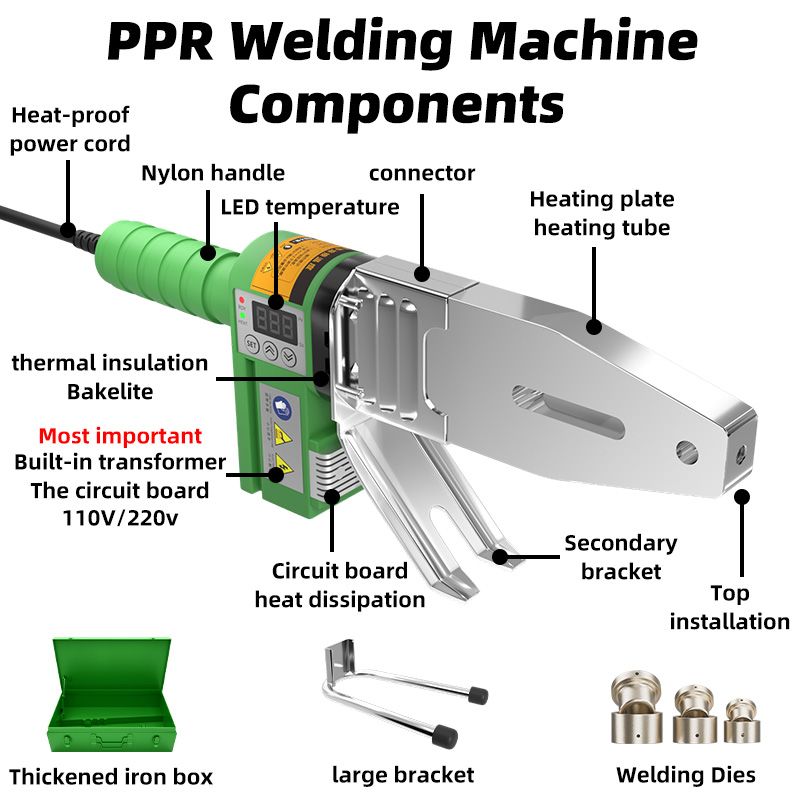

Ideal for smaller pipes and fittings, this machine heats the ends of the pipes and fittings to a temperature that allows them to be fused together. The process is straightforward, making it particularly useful for applications where precision and simplicity are paramount. Socket fusion is often employed in plumbing and gas distribution, where the integrity of the joint is critical.

Butt Fusion Welding Machine

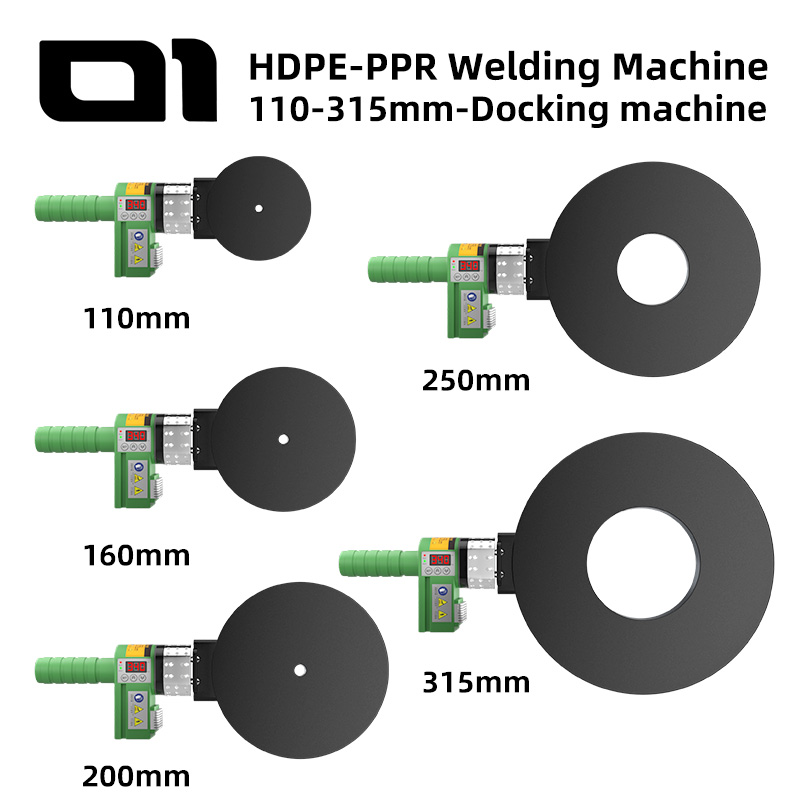

Suitable for larger pipes, this machine aligns the ends of the pipes and heats them until they can be pressed together to form a continuous bond. This method is highly effective for creating strong, durable joints in larger scale operations. Butt fusion is commonly used in industries such as water treatment and waste management, where the reliability of connections is crucial.

Electric Fusion Welding Machine

Utilizes electrical resistance to generate heat, creating a strong bond between two materials. This method is particularly advantageous for its speed and efficiency, making it ideal for high-volume production environments. Electric fusion is often preferred in the automotive and aerospace industries, where precision and speed are essential.

Precision and Accuracy

Fusion welding machines offer exceptional precision and accuracy, which is crucial for ensuring the integrity of the weld. This is particularly important in industries such as plumbing and gas distribution, where leaks or weak joints can lead to significant problems. Precision in welding not only enhances the quality of the joint but also ensures compliance with industry standards and regulations.

With advanced control systems, operators can manage the temperature and pressure precisely, ensuring each weld is consistent and reliable. This precision reduces the risk of material waste and rework, saving time and resources. The ability to produce consistent, high-quality welds is a major reason why fusion welding machines are preferred over other welding methods, especially in critical applications.

Strength and Durability

The fusion welding process creates joints that are as strong as the base materials. This is a significant advantage over other welding methods, where the joint can often be a weak point. Fusion welding ensures that the joined materials can withstand high pressure and stress, making it ideal for critical applications. This strength and durability are particularly beneficial in industries where safety and longevity are paramount, such as in infrastructure projects or automotive manufacturing.

In addition to strength, the durability of fusion-welded joints translates to fewer repairs and maintenance requirements. This reliability means that once a joint is made, it can be trusted to perform its function over the long term, minimizing downtime and associated costs. The long-lasting nature of these joints also contributes to the overall safety and efficiency of the systems in which they are used.

Versatility and Applications

Fusion welding machines are versatile tools that can be used for a wide range of materials and applications. Whether you’re working with HDPE, PVC, or metal, there’s a fusion welding machine that can meet your needs. This adaptability makes them a valuable asset in various industries, from construction to manufacturing. The ability to switch between different materials and applications with ease is a testament to the machine’s design and functionality.

Furthermore, the versatility of fusion welding machines extends to their use in both large-scale industrial projects and smaller, more specialized applications. This flexibility ensures that businesses of all sizes can benefit from the technology, whether they’re involved in large infrastructure projects or intricate manufacturing processes. The broad applicability of these machines ensures their continued relevance in a rapidly evolving industrial landscape.

Environmental Benefits

Fusion welding is an environmentally friendly process. Since it doesn’t require additional materials like adhesives or solvents, there’s minimal waste generated. This aspect is increasingly important as industries strive to reduce their environmental impact and adhere to stricter environmental regulations. The use of fusion welding machines supports sustainable practices by minimizing resource consumption and waste production.

Furthermore, the strong joints produced by fusion welding reduce the likelihood of leaks, which can be detrimental to the environment. In industries such as gas and water distribution, the prevention of leaks is crucial to conserving resources and protecting the environment. By ensuring that connections are secure and reliable, fusion welding machines contribute to the broader goal of environmental sustainability.

Cost Savings and Efficiency

Investing in a fusion welding machine can lead to significant cost savings over time. The precision and reliability of the welds reduce the need for repairs and maintenance, while the efficiency of the process minimizes labor costs. Additionally, the durability of the joints can extend the lifespan of the welded materials, leading to further savings. The initial investment in fusion welding technology is often offset by the long-term financial benefits it provides.

Moreover, the reduced need for additional materials, such as adhesives or fillers, lowers operational costs. The efficiency of the welding process itself means that projects can be completed more quickly, freeing up resources for other tasks. This cost-effectiveness is a compelling reason for many businesses to incorporate fusion welding machines into their operations, enhancing profitability and competitiveness.

Safety Features

The machines also produce minimal fumes and emissions, contributing to a safer working environment. In industries where air quality is a concern, the low-emission nature of fusion welding is a significant advantage. This focus on safety and environmental health not only protects workers but also aligns with industry standards and regulations, ensuring compliance and promoting responsible practices.

How to Choose the Right Fusion Welding Machine

When selecting a fusion welding machine, consider the following factors to ensure you choose the best tool for your needs:

Material Compatibility

Make sure the machine is compatible with the material you intend to process, such as high-density polyethylene (HDPE), polyacrylate (PPR), or metal. The right machine should be versatile enough to effectively handle different materials, ensuring optimal performance and results.

Size and Capacity

Consider the size and capacity of the machine to ensure it can handle the dimensions of your projects. A machine that matches your project’s scale will enhance efficiency and productivity, reducing the risk of delays or errors.

Ease of Use

Look for a machine with user-friendly controls and features that make the welding process straightforward and efficient. An intuitive interface and easy-to-understand instructions can significantly reduce the learning curve, allowing operators to become proficient quickly.

Durability and Maintenance

Choose a machine built with durable materials and designed for easy maintenance to ensure long-term reliability. A robust machine will withstand regular use and require minimal repairs, maximizing uptime and operational efficiency.

Conclusion

Fusion welding machines are invaluable tools that offer numerous advantages, from precision and durability to cost-effectiveness and environmental benefits. By understanding the different types of fusion welding machines and their applications, you can make an informed decision when investing in the right equipment for your projects. These machines not only enhance the quality of work but also contribute to safer and more sustainable industrial practices.

As technology continues to advance, fusion welding machines will likely become even more efficient and versatile, further solidifying their place in various industries. Whether you’re a contractor, engineer, or manufacturer, incorporating fusion welding machines into your operations can enhance the quality and efficiency of your work. Embracing these technologies ensures that businesses remain competitive and responsive to the demands of modern industrial processes.