In the realm of modern plumbing systems, especially those involving plastic pipes, PPR welding machines have emerged as indispensable tools. These machines are pivotal in ensuring a strong and durable connection between pipes, which is crucial for the integrity and longevity of plumbing systems. But what exactly is a PPR welding machine, and why has it become so essential in both residential and commercial construction projects? This comprehensive article will delve deeper into the basics of PPR welding machines, their uses, and the underlying mechanics of how they function.

What is a PPR Welding Machine?

A PPR welding machine is a specialized tool designed to join PPR (Polypropylene Random Copolymer) pipes and fittings. These machines utilize heat to melt the surfaces of the pipes, enabling them to fuse together seamlessly. The ability to create a seamless connection is what makes these machines vital, as they ensure that the plumbing system remains leak-proof and efficient over time.

PPR pipes are favored in plumbing systems for their durability, resistance to high temperatures, and their ability to withstand significant pressure. The role of the PPR welding machine in this context is to guarantee that these pipes are joined securely, thus preventing potential leaks and maintaining the system’s longevity. This makes them indispensable tools not only in residential settings but also in large-scale commercial projects where reliability is key.

Advantages of PPR Welding Machines

Beyond their primary function, PPR welding machines offer several advantages. They are used in a variety of applications ranging from water supply systems to heating installations. The seamless fusion they provide helps in maintaining the aesthetics and functionality of the plumbing system, ensuring that there are no visible joints that might compromise the system’s appearance or performance.

The Welding Process (Socket Fusion Welding)

PPR welding involves a meticulous process where the ends of the pipes and fittings are heated to a specific temperature. Once adequately heated, these ends are pressed together, allowing them to cool and form a solid, leak-proof joint. This process, known as socket fusion welding, is fundamental in achieving a seamless connection that can withstand the demands of modern plumbing systems.

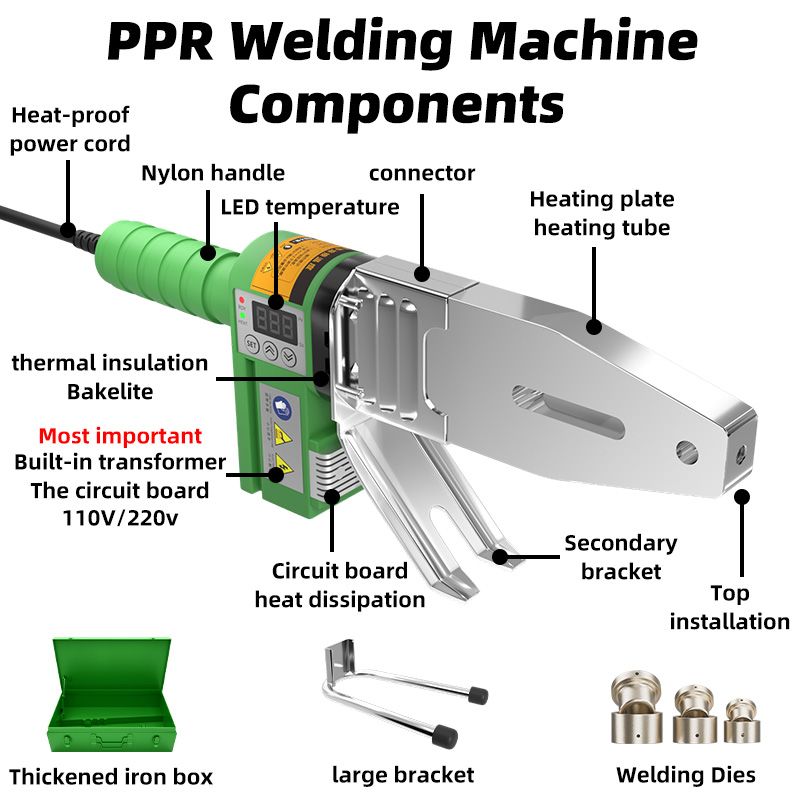

Key Components of a PPR Welding Machine

A typical PPR welding machine consists of several key components:

Heating Plate: This core component is responsible for heating the pipe ends. It is usually equipped with a non-stick coating to prevent the melted plastic from adhering to the surface, ensuring a clean and efficient welding process.

Thermostat: The thermostat plays a crucial role in regulating the temperature of the heating plate, ensuring consistent and safe operation. This consistency is vital in achieving the optimal weld.

Clamps: These are used to securely hold the pipes and fittings in place during the welding process, ensuring that the components are aligned correctly for a perfect weld.

Handle: The handle allows the user to apply the necessary pressure and keep the machine steady during the welding process, ensuring precision and control.

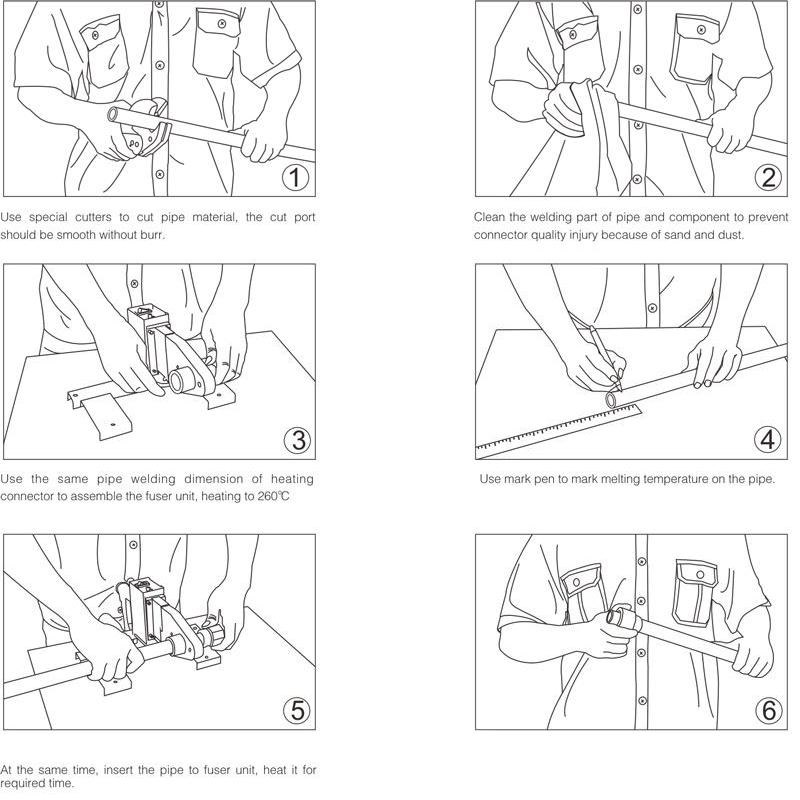

Step-by-Step Welding Procedure

Preparation: Begin by cutting the pipes to the desired length and cleaning the surfaces that will be welded. Proper preparation is key to ensuring a strong bond.

Heating: Insert the pipe ends into the heating plate and monitor them until they reach the correct temperature. This step requires precision to avoid overheating or underheating.

Joining: Once heated, swiftly remove the pipes from the heating plate and press them together. The speed and accuracy of this step are crucial in forming a seamless joint.

Cooling: Hold the pipes in place until the joint cools and solidifies. This patience ensures that the joint is robust and durable.

Benefits of PPR Welding

PPR welding machines create a bond between pipes that is as strong as the pipe itself. This strength is critical for systems that carry water under pressure, ensuring that the plumbing system can endure without failure over time.

The seamless fusion of pipe ends effectively prevents leaks, making PPR welding a trusted method for guaranteeing the integrity of plumbing systems. This reliability is particularly important in both residential and commercial applications where leaks can lead to significant damage and costs.

PPR pipes are naturally resistant to corrosion, and the welding process does not compromise this beneficial property. This resistance makes them an ideal choice for both hot and cold water supply systems, ensuring longevity and reducing maintenance needs.

Although the initial investment in a PPR welding machine might seem substantial, the long-term savings from reduced maintenance and repair costs render it a cost-effective choice for many projects. Over time, the reliability and durability of the welds can lead to significant financial savings.

PPR welding machines support eco-friendly construction practices. By ensuring leak-proof and durable plumbing systems, they contribute to water conservation and reduce the need for frequent replacements, aligning with sustainable building practices.

How to Choose the Right PPR Welding Machine

When selecting a PPR welding machine, consider the size and scope of your project. For small projects, a manual machine may suffice, while larger projects may benefit from an automatic machine’s enhanced capabilities. Assessing the demands of your project will help determine the most suitable machine.

Balancing the cost of the machine with its features and your specific needs is crucial. While it’s tempting to opt for the most advanced model, it’s essential to choose one that fits within your budget without sacrificing necessary features. Consider the long-term benefits and potential savings when evaluating the cost.

Ensure the machine is user-friendly, especially if you have limited experience with welding. Machines with intuitive controls and clear instructions can significantly ease the learning curve, allowing even novice operators to achieve professional results.

Choose machines from reputable manufacturers known for quality and reliability. A well-known brand often guarantees a certain level of performance and customer support, providing peace of mind and assurance in your purchase.

Consider any additional features that might be beneficial for your specific needs. Some machines offer customizable settings or specialized attachments that can enhance performance and versatility, allowing you to tailor the machine to your unique requirements.

Maintenance and Safety Guidelines

To ensure your PPR welding machine operates efficiently, perform regular maintenance. This includes cleaning the heating plate to prevent residue build-up, checking the thermostat for accurate temperature regulation, and inspecting the clamps for signs of wear and tear. Regular maintenance not only extends the life of the machine but also ensures consistent performance.

Operator Safety

Temperature Control: Always monitor the machine’s temperature to prevent overheating, which can compromise the quality of the weld and pose safety risks.

Protective Gear: Wear gloves and safety goggles to protect against burns and debris. Proper attire is essential for ensuring operator safety during the welding process.

Proper Ventilation: Ensure the work area is well-ventilated to avoid inhaling fumes from melted plastic. Adequate ventilation helps maintain a safe and comfortable working environment.

Conclusion

PPR welding machines are an integral part of modern plumbing installations, providing the strength, durability, and leak-proof joints required for efficient water supply systems. Whether you’re a professional plumber or a DIY enthusiast, understanding the basics of PPR welding machines will help you make informed decisions and achieve the best results in your projects. With the right machine and proper technique, you can ensure a reliable and long-lasting plumbing system, contributing to the overall success and sustainability of your construction efforts. By investing in a quality PPR welding machine and adhering to best practices, you can significantly enhance the performance and reliability of your plumbing installations.