Choosing the right PPR welding machine panel size can feel daunting. With so many models available, it’s easy to get overwhelmed. Yet, understanding panel sizes is crucial for effective welding, project efficiency, and cost control. This guide will help you evaluate different options and select the most suitable size for your needs.

What is a PPR Welding Machine and Why Does Panel Size Matter?

A PPR welding machine is essential for joining PPR pipes, widely used in plumbing and heating systems. The machine heats and melts pipe ends, allowing them to fuse into a leak-proof joint.

The panel size refers to the heating plate dimensions, which determine compatibility with different pipe diameters. Choosing correctly is critical for strong, reliable welds.

Key reasons why panel size matters:

- Compatibility with various pipe diameters

- Impact on weld quality and efficiency

- Influence on project scale and cost

Selecting the correct panel size ensures optimal performance and reduces risks of rework.

Understanding PPR Welding Machine Panel Sizes

Panel sizes typically range from 20–63mm, 20–110mm, to 20–160mm. Each range fits specific project requirements:

- Smaller panels are perfect for residential projects or limited spaces.

- Mid-sized panels suit commercial installations.

- Larger panels handle industrial jobs and wide pipe ranges.

When evaluating panel sizes, consider:

- Pipe diameters in your project

- Project size and demands

- Portability versus power balance

Aligning the machine with current and future needs ensures efficiency and cost-effectiveness.

Common Panel Sizes and Their Applications

Different panel sizes match different project scopes:

- 20–63mm: Residential plumbing and small-scale repairs. Compact and easy to use in tight spaces.

- 20–110mm: Ideal for commercial plumbing and mid-size projects.

- 20–160mm: Best for industrial use, covering extensive piping networks.

Choosing the right panel avoids extra costs and guarantees weld consistency.

How to Choose the Right Panel Size for Your Project

The ideal size depends on your project’s specific demands:

- Check pipe diameters – ensure compatibility.

- Assess project scope – residential, commercial, or industrial.

- Consider budget – larger panels cost more but add versatility.

- Use a PPR size chart – confirm precise matching for efficient results.

Comparing Welding Machine Sizes: Portability and Usability

Machine size affects portability and usability.

- Smaller machines: Lightweight, easy to transport, perfect for mobile work.

- Larger machines: Provide more power and stability, but harder to move; best for heavy-duty or stationary projects.

Consider:

- Ease of movement and transport

- Project demands and power needs

- Work environment and available space

PPR Welding Machine Sets: What’s Included and Why It Matters

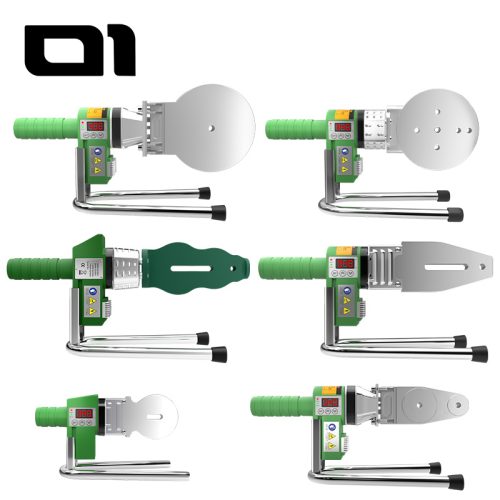

A complete set is more than just the machine. Most sets include:

- Multiple heating plates

- Alignment and fixing tools

- Protective storage case

A well-equipped set prevents delays, ensures compatibility, and improves efficiency.

Using the PPR Size Chart for Accurate Selection

The PPR size chart is a simple but essential tool. It shows which panel matches which pipe diameter, helping prevent mistakes. Always align your project’s pipe sizes with the chart to ensure precise results.

Key elements on the chart include:

- Pipe diameter ranges

- Matching panel recommendations

- Typical applications

Key Features to Consider Beyond Panel Size

Panel size is important, but additional features enhance performance and safety:

- Adjustable temperature control & overheating protection

- Power rating for fast heating

- Strong build quality and durability

- Compatibility with PPR, PE, and other plastic pipes

- Easy cleaning and low maintenance

Maintenance, Safety, and Longevity Tips

Proper maintenance extends machine life and ensures safety:

- Clean heating plates after every use

- Inspect power cables and connections

- Store in dry, dust-free environments

- Always wear protective gear

- Regularly test safety functions

Consistent checks guarantee reliable performance and protect investment value.

Conclusion: Making the Best Choice for Your Needs

Choosing the right PPR welding machine panel size requires understanding pipe diameters, project scale, and usability needs. By considering these factors, you can make informed decisions, reduce costs, and ensure strong welds.

At HaoTian, we manufacture and export full-size PPR welding machines (20–63mm, 20–110mm, 20–160mm) with CE certification. Whether for residential, commercial, or industrial applications, our machines deliver reliable performance for global projects. Contact us today for specifications and a quotation.