Introduction

High Density Polyethylene (HDPE) is widely used in pipelines, water systems, drainage networks, and industrial applications. Strong and leak-free connections are essential for durability, which makes HDPE welding a critical process. Whether you are working with HDPE pipe, HDPE plastic sheets, or polyethylene sheets, selecting the right HDPE welder is the key to achieving long-lasting joints. This guide explains how to choose the best HDPE butt fusion machine based on pipe size, project needs, and technical features.

Core Features of HaoTian HDPE Butt Fusion Machines

- Non-stick black Teflon heating plate – Prevents material from sticking during the weld and ensures smooth, professional joints.

- Digital temperature control – Provides accurate heat regulation, making it easier to weld HDPE pipes with precision.

- Uniform heating technology – Guarantees consistent fusion across the surface, resulting in maximum joint strength.

- Versatile welding capability – Suitable for HDPE welding rods, HDPE sheets, and a wide range of pipeline projects.

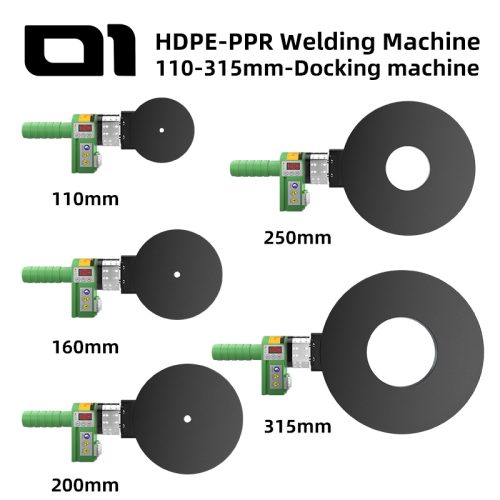

Model Specifications and Applications

- 110mm HDPE butt fusion welder – Ideal for small HDPE pipe welding jobs such as household water lines and local repairs.

- 160mm HDPE welding machine – Best for small-to-medium projects in water supply and drainage systems.

- 200mm HDPE welder – A reliable choice for municipal HDPE pipe welding and medium-scale construction.

- 250mm HDPE fusion machine – Suited for industrial pipeline welding, including high density plastic and gas pipe networks.

- 315mm HDPE butt fusion welder – Designed for large-scale municipal infrastructure, long-distance HDPE pipe welding, and heavy-duty projects.

How to Weld HDPE and Choose the Right Machine

- Match by Diameter – Select an HDPE fusion welder that matches your pipe size (110mm, 160mm, 200mm, 250mm, or 315mm).

- Consider the Application – For HDPE plastic sheets or fabrication, ensure compatibility with flat welding options. For pipelines, choose butt fusion models.

- Use Proper Equipment – For small-scale repairs, HDPE welding guns and HDPE welding rods may be sufficient. For full-scale pipeline projects, a butt fusion machine is essential.

- Focus on Temperature Control – HDPE requires precise heating; machines with digital temperature adjustment ensure consistent results.

- Project Scale – Small jobs = 110–160mm; large projects = 200–315mm.

Answering Common Questions

- Can HDPE be welded? – Yes, HDPE can be welded using butt fusion, extrusion welding, or HDPE welding rods.

- How to weld HDPE pipe? – Heat both ends with a Teflon-coated heating plate, align the pipes, and apply pressure until they fuse.

- Can you plastic weld HDPE? – Yes, but always use the right machine, such as an HDPE butt fusion welder or extrusion welder, for strong joints.

Conclusion

Selecting the right HDPE welding machine depends on pipe size, project requirements, and application type. HaoTian HDPE butt fusion welders are equipped with non-stick Teflon plates, digital temperature control, and robust designs, making them suitable for HDPE pipes, HDPE sheets, and high density polyethylene welding projects. Whether you need a compact HDPE welder for small pipes or a 315mm butt fusion machine for municipal pipelines, HaoTian provides professional solutions for reliable and durable connections.