In modern pipeline installation and maintenance, the PPR welding machine (also known as a hot melt welding machine or socket fusion welder) plays a vital role. Whether it’s domestic water supply systems, commercial plumbing, or large-scale municipal projects, the right welding machine ensures durable, leak-proof, and professional-quality connections. With so many models available, choosing the right one requires a clear understanding of pipe size, material compatibility, and machine performance.

Why the Right Welding Machine Matters

The service life of a pipeline system depends heavily on the quality of its welded joints. Poorly welded pipes can lead to leaks, cracks, or even costly failures. Since PPR pipe welding requires a precise temperature of 260 ± 10°C, maintaining stable and accurate heat is crucial:

- Too low → Weak joints that may separate under pressure.

- Too high → Burned or deformed pipe surfaces.

That’s why choosing a welding machine with reliable digital temperature control, ±1°C precision, and stable heating performance is essential for any project.

Key Factors to Consider

1. Project Scale and Application

- Household & DIY projects: Portable socket fusion welders (Φ20–63mm) are lightweight, easy to use, and suitable for small-diameter pipes.

- Commercial & residential installations: Medium-sized machines handling Φ40–75mm pipes with multiple dies are ideal.

- Large-scale or municipal projects: Butt fusion welders or electrofusion machines for pipes Φ110mm+, ensuring seamless and durable joints.

2. Pipe Size and Interchangeable Welding Dies

Choosing the right die size is critical for compatibility:

- Small pipes (Φ20, Φ25, Φ32mm) – Common in domestic water supply.

- Medium pipes (Φ40–75mm) – Often used in residential or light commercial projects.

- Large pipes (Φ90–160mm+) – Required for industrial, municipal, and gas pipeline projects.

Always look for machines with interchangeable Teflon-coated welding dies, which provide smooth heat transfer, prevent sticking, and support multiple pipe diameters.

3. Compatible Pipe Materials

A high-quality PPR welding machine should support multiple thermoplastic pipe materials:

- PPR (Polypropylene Random Copolymer) – Widely used for hot and cold water systems.

- PB (Polybutylene) – Flexible and durable, suitable for heating and floor piping systems.

- PE & HDPE (Polyethylene / High-Density Polyethylene) – Common in municipal water, gas, and industrial pipeline systems.

This multi-material compatibility allows one machine to be used across various applications, making it more versatile and cost-effective.

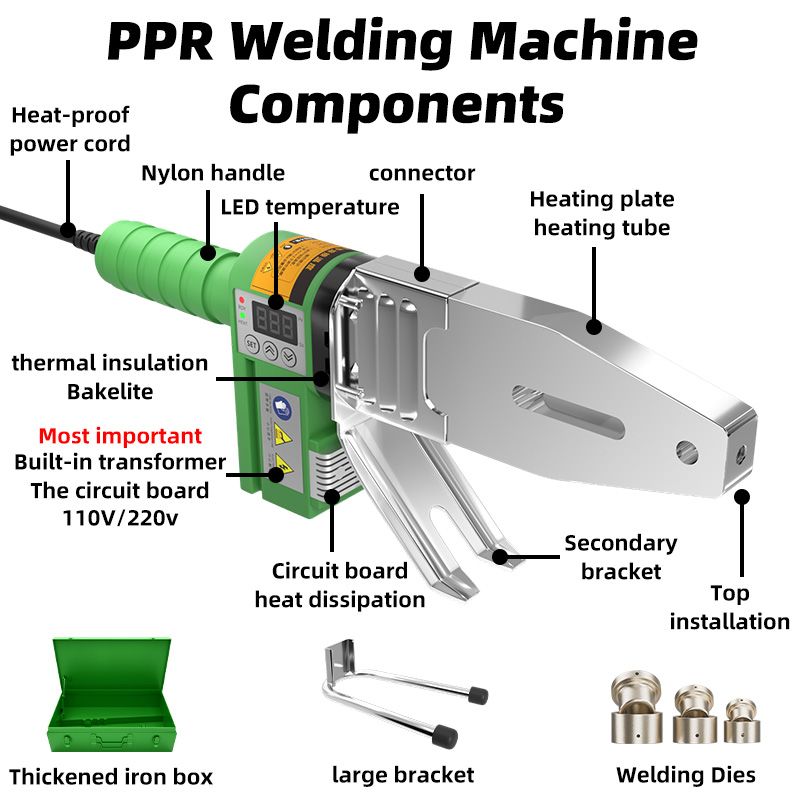

4. Temperature Control System

- Digital LED display – Easy monitoring of real-time temperature.

- ±1°C accuracy – Guarantees professional weld quality.

- Memory function – Remembers the last working setting for convenience.

5. Heating Components

- 20mm thick aluminum or stainless-steel heating plate – Delivers fast and uniform heating.

- Ceramic core or heating tube – Ensures efficient, long-lasting heat generation.

- Teflon-coated dies – Prevent sticking, ensure smooth fusion, and extend die lifespan.

6. Circuit System & Heat Dissipation

- Independently developed circuit board – Stable performance and reliable power output.

- Transformer supporting 110V/220V – Suitable for international use.

- Chip heat sink – Prevents overheating, prolonging electronic component life.

7. Safety & Durability

- Insulated nylon housing & anti-scald handles – Protect users during operation.

- Overheat protection system – Prevents machine damage.

- Iron storage box – Adds portability and durability for fieldwork.

8. Frequency of Use

- Occasional or DIY use – Choose a compact, budget-friendly model.

- Professional plumbers & contractors – Opt for high-power machines with precise temperature control and longer durability.

Common Types of Welding Machines

- Socket Fusion Welding Machine

- Best for PPR and PB small-diameter pipes (Φ20–63mm).

- Compact and easy to operate.

- Butt Fusion Welding Machine

- Suitable for HDPE and PPR pipes with large diameters (Φ110mm+).

- Delivers seamless, high-strength joints.

- Electrofusion Welding Machine

- Uses electrofusion fittings with embedded resistance wires.

- Provides extremely accurate and secure connections, ideal for gas or high-pressure pipelines.

How to Identify a Reliable Welding Machine

- Check the brand reputation and industry certifications.

- Test the temperature accuracy and stability.

- Inspect the heating plate thickness and build quality.

- Confirm the availability of spare parts and welding dies for multiple pipe sizes.

Conclusion

The best PPR welding machine should combine accurate temperature control, strong heating performance, multi-material compatibility, and reliable safety features. Whether your project involves PPR water pipes, PB heating systems, or HDPE municipal pipelines, choosing the right machine and welding dies ensures stronger joints, reduced leaks, and long-lasting performance.

At Haotian Machinery, we offer a full range of welding equipment, including PPR hot melt welding machines, constant temperature welders, electrofusion machines, HDPE butt fusion welders, same-layer drainage welders, welding dies, and pipe cutters. With advanced R&D, strict quality control, and OEM/ODM services, we provide high-quality pipeline welding solutions trusted by professionals worldwide.