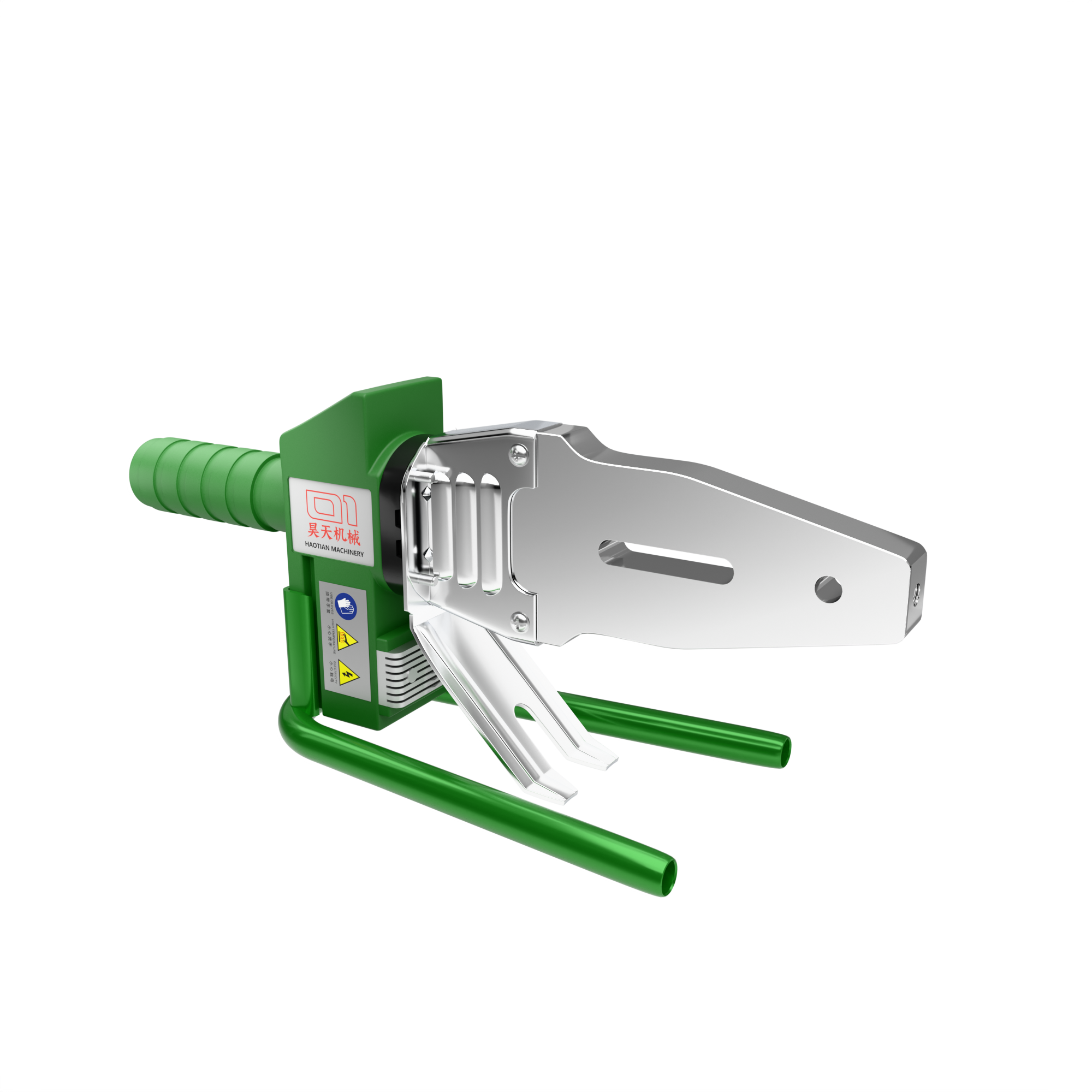

In the intricate world of fluid conveyance – from the water flowing in our homes to complex industrial networks – the integrity of every joint is paramount. Enter the PPR (Polypropylene Random Copolymer) Fusion Machine, often called a PPR heat welder or hot melt machine. This unassuming tool is not merely a device; it’s the cornerstone technology enabling the widespread adoption and reliability of PPR piping systems across countless industries.

Where the Heat is Applied: Core Applications

PPR fusion machines are indispensable wherever PPR pipes are installed:

- Plumbing & Water Supply (Potable & Non-Potable): The undisputed king of residential, commercial, and municipal cold and hot water systems. Fusion welding creates seamless, leak-proof joints essential for pressure integrity and hygiene.

- HVAC (Heating, Ventilation & Air Conditioning): Used extensively for heating circuits (radiators, underfloor heating), chilled water lines, and condenser water systems due to PPR’s thermal resistance.

- Industrial Process Piping: Conveying chemicals (where compatible), compressed air, food-grade liquids, and other process fluids in factories, labs, and treatment plants.

- Renewable Energy Systems: Integral to solar thermal installations for connecting collectors and circulating heat transfer fluids.

- Agricultural Irrigation: Providing durable, corrosion-resistant piping networks.

Why Fusion Reigns Supreme: The Irreplaceable Advantages

The PPR fusion machine delivers benefits that traditional joining methods (like mechanical fittings or solvent welding) simply cannot match for PPR:

- Leak-Proof, Homogeneous Joints: The core magic. The machine melts the pipe end and fitting socket simultaneously. When joined and cooled, the materials fuse molecularly, creating a single, monolithic piece of plastic at the joint. This virtually eliminates the primary failure point in piping systems: leaks.

- Unmatched Long-Term Reliability & Durability: Fused joints exhibit strength often exceeding the pipe itself. They resist vibration, pressure surges, and thermal cycling far better than mechanical connections, ensuring decades of trouble-free service. This directly translates to reduced maintenance costs and system downtime.

- Corrosion & Scale Resistance (Inherited): By enabling the use of PPR pipe, fusion welding inherits its core benefits: complete immunity to rust and electrolytic corrosion, and minimal scaling – crucial for water quality and flow efficiency.

- Speed and Efficiency: Modern fusion machines heat and join pipes rapidly. A skilled operator can create numerous reliable joints much faster than assembling complex mechanical fittings or waiting for solvents to cure, significantly accelerating project timelines.

- Cost-Effectiveness (Lifecycle): While the machine is an investment, the long-term savings are substantial: minimal material waste, reduced labor time, near-zero maintenance on joints, and avoidance of costly leak repairs and water damage.

- Cleanliness & Hygiene: The process uses only heat, no chemicals, solvents, or lubricants that could contaminate potable water lines or sensitive process fluids. The smooth interior of the fused joint also prevents bacterial harborage points.

- Versatility & Simplicity: Machines handle a wide range of standard pipe diameters commonly used in target industries. The process, while requiring skill, is relatively straightforward to learn and perform consistently.

The Engine of Industry Adoption

The PPR fusion machine isn’t just a tool; it’s the critical enabler that made PPR pipe a dominant global solution:

- Enabling the PPR Revolution: Without reliable, fast fusion technology, the installation advantages and long-term benefits of PPR pipe could not be fully realized on a large scale. The machine made PPR systems practical and economically viable.

- Standardization & Quality Assurance: Fusion procedures are well-defined (e.g., heating times based on pipe diameter, ambient temperature). Proper machine use ensures consistent, high-quality joints that meet international standards, providing engineers and installers with confidence.

- Driving Innovation: Demand for faster, more user-friendly, and more precise welding has led to continuous machine evolution: digital temperature control, improved heating element designs, ergonomic handles, and alignment features.

Modern Machines: Precision Engineering

Today’s PPR fusion machines reflect decades of refinement:

- Precise Digital Thermostats: Ensure optimal, consistent welding temperature for perfect fusion.

- Fast Heating Elements: Reduce wait times between welds.

- User-Friendly Interfaces: Clear displays and controls.

- Robust Construction: Built for demanding job sites.

- Safety Features: Overheat protection, stable stands.

Conclusion: The Indispensable Bond

From the water mains beneath our cities to the intricate pipes within hospitals and factories, PPR piping systems form a vital, often invisible, infrastructure. The PPR fusion machine is the silent, essential force behind their integrity. By creating molecularly fused joints that are stronger, more reliable, and longer-lasting than the pipe itself, this technology underpins the safety, efficiency, and durability of modern fluid transport. It’s not just a welding tool; it’s the fundamental instrument ensuring our water flows cleanly, our buildings stay dry, and our industries operate smoothly. As PPR continues to be the material of choice for countless applications, the fusion machine remains its indispensable partner, quietly building the connections that hold our world together.