I. Post-Use Daily Procedures

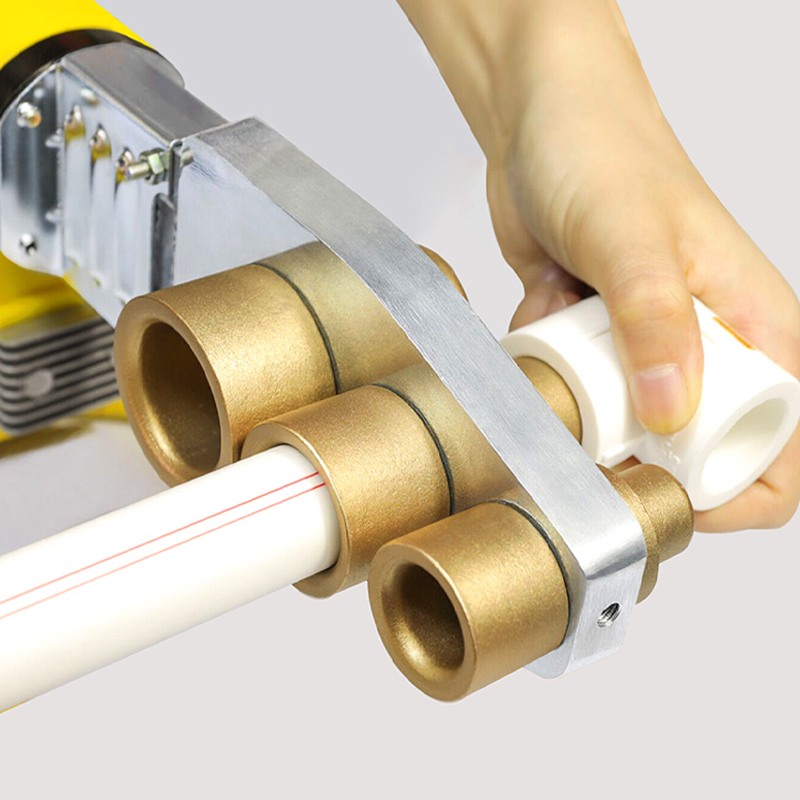

- Cleaning Heating Molds

- Wait until temperature drops below 80°C, wipe off plastic residues with pure cotton cloth

(Strictly prohibit metal brushes or chemical solvents) - Remove stubborn carbon deposits with wooden scrapers gently to avoid damaging PTFE coating

- Wait until temperature drops below 80°C, wipe off plastic residues with pure cotton cloth

- Inspecting Power Cords & Plugs

- Check for exposed copper wires, scorch marks, or deformation

- Immediately stop use and replace with genuine parts if abnormalities are found

II. Periodic Component Maintenance

| Component | Maintenance Interval | Key Procedures |

|---|---|---|

| Heating Molds | Every 3 months | Check coating integrity after disassembly; replace if peeling area >5mm² |

| Temp Sensors | Every 6 months | Clean probes with anhydrous alcohol; recalibrate (return if error >±3°C) |

| Fan Filters | Monthly | Remove dust with vacuum; wash with water and dry thoroughly (clogging causes overheating) |

III. Long-Term Storage Protocol

- Apply high-temperature anti-rust grease on mold surfaces, wrap with grease-proof paper

- Store in environment with humidity <60%, avoid temperatures below -15°C

*Notes:

- PTFE = Polytetrafluoroethylene

- All measurements strictly follow original specifications*